|

|

Post by 1dave on Nov 20, 2013 17:58:45 GMT -5

I wonder how that saw came about because the guts are commercial? Maybe someone's HP fell out of the back of someones truck going down the highway lol. Or maybe they sold kits at one time who knows. I know....I bet an employee stole it. Something like Johnny Cash's Cadillac he stole one piece at a time? |

|

ash

spending too much on rocks

Prairieville, Louisiana

Prairieville, Louisiana

Member since July 2012

Posts: 361

|

Post by ash on Dec 4, 2013 0:20:11 GMT -5

Finally, some changes. First I replaced the cut-off switch which was oil filled. Cheap and easy, and turns off with the lightest tug.  A MAJOR problem with this switch is when you pull the vice carriage back, it is EASY to bump the wire and turn the saw on. You won't like it when the hood is up, and the saw is running! Could you put a PVC conduit clamp over the switch and drill a hole for the wire? It would be a cheap thing to try. I googled covered light switches and this is what came up. www.thingiverse.com/make:13815 |

|

|

|

Post by 1dave on Dec 4, 2013 7:30:07 GMT -5

Thanks Ash, a simple solution!

I've wondered about splitting a 6" piece of PVC and clamping it over the handy box to keep oil from dripping in.

The big problem was bumping the other end of the wire - inside the box - and turning the saw on.

|

|

|

|

Post by Peruano on Dec 4, 2013 8:40:17 GMT -5

1Dave, Question on your in-line switch add-on, since I'm in the process of designing an auto-off (end of cut) switch for my primary slab saw. Your second switch is only of value if you remember to turn it off before opening the saw which is also true of the one with the chain if you just remembered to securely move the auto switch from its "tender" off state to a full off throw of the switch == or am I missing something?

The problem of oil baths is due to a switch that is not fully past the center of its action and therefore springs back to its on position due to slack in the vice sled chain?

For the true old timers, I'd propose (theoretically) a mercury switch which once the mercury flowed away from the contacts it would ideally stay "off" until reset. Much like the old time thermostats.

But back to the question of a foolproof "no bath switch" the solution would be a switch activated by the chain that did successfully pass the threshold to"stay off". Or a contact switch on the cover/lid that disengaged as soon as the lid was lifted even a couple of mm (more of a safety switch than an auto-off). Perhaps that would be precluded by the oil escaping by any amount of lid opening or ??

I mention the lid switch option because my home-made saw came with what appeared to be such a switch (disconnected) and I've never analyzed the electrical connection or mechanics of the fabricator's missing top that would have activated it, to re-install. It always seemed to me to be a switch that would have meant a "brief" oil bath - better than a bigger one but still undesirable. Sorry for the ramble. Tom

|

|

|

|

Post by 1dave on Dec 4, 2013 9:10:44 GMT -5

Peruano Hi Tom, Mercury and contact switches cost money. Both switches were $0.75 each at Home Depot. This is a very inexpensive solution. You have to be careful drilling the hole, any "prying" will break the plastic. I did consider drilling down the toggle end, tapping, and putting in a 6-32 screw to attach the wire. THE PROBLEM is bumping the other end of the turn-off wire inside the box that attaches to a jack chain that can be length adjusted at the vise. Pull back the vise, bump the short wire, which shoves the toggle, and the saw turns on with a free oil shower. I could "just" pull the 20 amp twist plug each time, but that is a hassle. I MUST REMEMBER three things: ONE: Before opening the lid LOOK to see if the first switch is off! TWO: Before opening the lid LOOK to see if the first switch is off! THREE: Before opening the lid LOOK to see if the first switch is off! I still sometimes scare my little self.

|

|

|

|

Post by Peruano on Dec 4, 2013 10:25:54 GMT -5

1 Dave, I understand. I was overthinking your solution - hey when I'm hearing from someone who works on nuclear power plants, you know it can get complicated, sophisticated, and expensive. I was raised on a farm a few hundred yards from the Clinton Lake shoreline where the Clinton Power Plant was built (Illinois). I will install my end of cut switch "in line" with my existing switch. Thanks for clarification. Tom BTW. My woodstove is in a direct line with the oil throw if I open my saw while the blade is running. I won't forget (or if I do, I'll never admit on this forum to burning down my workshop). Wish me good luck. Tom Edit: I went ahead with the auto-off switch stimulated by this discussion, photo below, but the full description will be placed in a separate thread (auto-off switch for slab saw) to avoid diluting this thread. Tom  |

|

|

|

Post by 1dave on Dec 4, 2013 19:58:02 GMT -5

Peruano Tom, I can't imagine you diluting anything. On the Power Houses, complicating is the name of the game. The more it costs, the more everyone at the top gets. Why use a switch when you can do the same thing with 35 limit switches, 40 mercury switches and 50 pages of diagrams?

|

|

The Dad_Ohs

fully equipped rock polisher

Take me to your Labradorite!!

Take me to your Labradorite!!

Member since September 2012

Posts: 1,860

|

Post by The Dad_Ohs on Dec 13, 2013 21:31:53 GMT -5

as opposed to using tile in the saw... get yourself some red fireplace brick and place them under the slab tray and along the opposite wall from the blade... I only use 3 1/2 gallons of oil in my 18" saw and if I could make it less I would 1 1/2 - 2 gallons would be ideal for me!!

|

|

|

|

Post by 1dave on Dec 14, 2013 10:37:17 GMT -5

as opposed to using tile in the saw... get yourself some red fireplace brick and place them under the slab tray and along the opposite wall from the blade... I only use 3 1/2 gallons of oil in my 18" saw and if I could make it less I would 1 1/2 - 2 gallons would be ideal for me!! I agree with all but the red firebrick. When I got the saw it was filled with them. They had decayed and crumbled, soaked with oil and sludge. I had to throw them away. Luckily I had a lot of FREE 1'X1' granite tiles on hand and filled the bottom with them except under the blade. Works well and saves around 3 gallons of oil. Perhaps that would be a use for all those ugly agate butt ends no one wants. |

|

The Dad_Ohs

fully equipped rock polisher

Take me to your Labradorite!!

Take me to your Labradorite!!

Member since September 2012

Posts: 1,860

|

Post by The Dad_Ohs on Dec 17, 2013 16:47:29 GMT -5

as opposed to using tile in the saw... get yourself some red fireplace brick and place them under the slab tray and along the opposite wall from the blade... I only use 3 1/2 gallons of oil in my 18" saw and if I could make it less I would 1 1/2 - 2 gallons would be ideal for me!! I agree with all but the red firebrick. When I got the saw it was filled with them. They had decayed and crumbled, soaked with oil and sludge. I had to throw them away. Luckily I had a lot of FREE 1'X1' granite tiles on hand and filled the bottom with them except under the blade. Works well and saves around 3 gallons of oil. Perhaps that would be a use for all those ugly agate butt ends no one wants. nahhhh... if you have a bunch of agate butts you don't need let me know.... I can always find use for them for garden borders and what not.... I'll even pay for postage to ship 'em here. As far as the red brick degrading on you... if you don't clean out the saw and wash off the brick too, then they will decay... I have 4 red brick in my saw at the moment and when I do my clean out I just toss them on the ground and hit them with he hose, once they dry, which here in Florida on a good day is about 7-10 minutes, they go right back in & I have had them in my saw for almost a year now with no noticeable decay of the bricks. of course you can always use concrete blocks.... the 4 inch blocks are solid, but kind of heavy, and are equal to 4 bricks in size... I am looking for 4 of them to put it my saw next to lower the amount of oil I use... found 2 left overs from a job near my house, just need 2 more. I don't have access to tile so haven't used it, besides they are not tall enough unless you stack them. |

|

|

|

Post by 1dave on Dec 19, 2013 13:14:21 GMT -5

I like david 's bottomless saw sitting in a pan for clean-out purposes! Mucking the 12" What if it was hinged and had a jack attached? |

|

|

|

Post by DirtCleaner on Dec 19, 2013 14:58:25 GMT -5

The beauty of the removable pan is that you can then just dump (with a little scraping) the contents into you filtering system. Next time though, I will only dump out the liquid and discard the rock snot on the bottom. Seemed to be too much work for the few drops of oil that I recovered. Any average to poor sheet metal worker could make a pan for any bench model. More effort would be needed to do this to a model with legs. |

|

|

|

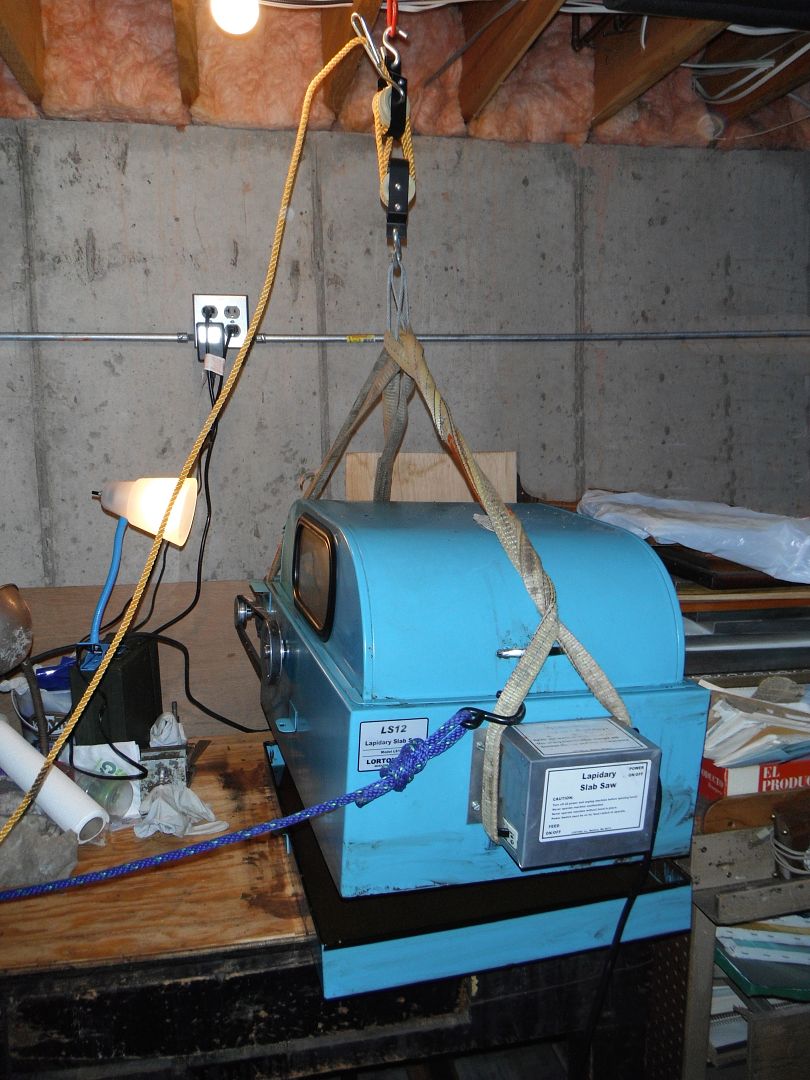

Post by 1dave on Feb 13, 2014 17:08:26 GMT -5

I like the Lortone design of a separate oil pan that the rest of the saw can be lifted out of for cleanup.

A spare pan could be used for instant saw continuation while the pan is being worked on!

|

|

|

|

Post by 1dave on Aug 1, 2017 21:26:11 GMT -5

PB Disaster - Ended up totally re-writing this and deleting a post.

|

|