|

|

Post by Pat on Jan 6, 2014 16:34:11 GMT -5

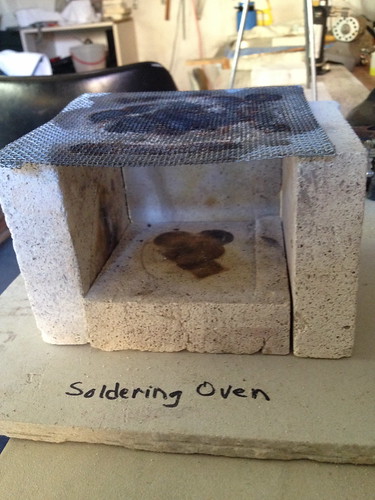

Here is a little soldering oven I made.  IMG_1946 IMG_1946 by Pat6489, on Flickr Bought these three bricks at an estate sale. They look like firebricks to me, but I'd like to be sure. From left to right: Snowball. This is a family name! How fun! It came from England to the California coast as ballast in the mid-1800s. They were tossed to make room for wheat and other items that acted as ballast on the way back to England. Middle brick says Stockton. From Stockton, CA in the early 1900s. Right brick says Carnegie, which is from the Stockton plant also. Web says they are firebricks, but I want to know how I can identify them for sure.  IMG_1950 IMG_1950 by Pat6489, on Flickr Color is not the identifier, but what is? Thanks. |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 6, 2014 17:13:14 GMT -5

I like it Pat. It is safe and has great drainage. I learned that flux is best kept over there. It is not good to have around your metal working area. Nasty stuff.

|

|

|

|

Post by Pat on Jan 6, 2014 18:19:28 GMT -5

I like it, too. Concentrates the heat, so the process goes faster.

Do you know how to tell the difference between a regular brick and a firebrick?

|

|

|

|

Post by pghram on Jan 6, 2014 21:18:25 GMT -5

So, would the piece sit on the screne & be heated from below?

Rich

|

|

|

|

Post by Pat on Jan 6, 2014 21:21:10 GMT -5

pghram, the item would sit on the screen. Torch head heats it from the bottom. I cut those firebricks in half length-wise and width-wise.

|

|

|

|

Post by pghram on Jan 6, 2014 21:27:03 GMT -5

Pat, thanks for the info, I'm trying to learn about the smithing part, with absolutely no experience.

Rich

|

|

|

|

Post by Pat on Jan 6, 2014 21:29:20 GMT -5

Rich, you don't need the little oven, but you must have a firebrick.

Take a look at Joe Silvera's book on soldering . Very good for a beginner.

Also, check out Lexi Erickson's videos (youtube) on various aspects

|

|

|

|

Post by pghram on Jan 6, 2014 21:36:15 GMT -5

Pat, thanks, I will. I have watched several videos by Soham Harrison on youtube.

Rich

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 6, 2014 22:19:29 GMT -5

Bickerstaff Brick Company mined a lot of clay along the Chattahoochee River. The brick companies took the clay hills along the river thru Atlanta leaving flat lots for industrial sites. They are still getting the clay and have moved down to about 6 miles north of my house. For probably 20 miles over many years. The clay is high quality brick clay. Those look like kiln brick. It is usually beige/yellow. If you our your neighbors have fire places you can see the color. The lite color assists in reflectivity. These old kilns brick kilns are here and there along the river. I think Snuffy collects bricks..  |

|

snuffy

Cave Dweller

Member since May 2009

Posts: 4,319

|

Post by snuffy on Jan 6, 2014 22:35:50 GMT -5

|

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 6, 2014 22:43:59 GMT -5

That caliche you guys have is a giant brick.

|

|

|

|

Post by Pat on Jan 7, 2014 1:56:36 GMT -5

snuffy, how can I tell if a brick is a firebrick instead of a regular brick?

|

|

snuffy

Cave Dweller

Member since May 2009

Posts: 4,319

|

Post by snuffy on Jan 7, 2014 5:29:42 GMT -5

snuffy, how can I tell if a brick is a firebrick instead of a regular brick? Pat,seems like the light tan bricks are the ones used in the fireplaces I've seen,and are a slightly larger size than regular bricks.Just an observation. snuffy |

|

jamesp

Cave Dweller

Member since October 2012

Posts: 36,602

|

Post by jamesp on Jan 7, 2014 7:35:24 GMT -5

This is a typical modern 1/2 fire brick Pat. No holes. Like Snuffy said they are a bit larger. They are hard and have a bit of ring. Old bricks were often made in lower temperature kilns and are softer and hard to break. Rarely have holes. Modern brick is fired at around ceramic furnace temps and is brittle and has a ring. Those bricks you have look old and may defy modern brick dimensions and manufacturing methods. Me personally would be surprised if you could damage any brick with small heat sources for jewelry making. My initial thought. But you Pat may have some real powerful stuff going on over there.... The heat in a fire place is extreme and hot enough to make bricks glow.  |

|

|

|

Post by pauls on Jan 9, 2014 3:16:21 GMT -5

Firebricks are made from fireclay. (duh). Fireclay is a type of clay with high Aluminium Oxides which allow it to be used in high temperature environments (Furnaces and Kilns) without melting. Firebricks are always a light color.

For jewellery making you are better of with insulating bricks, same stuff just that when they are made a high concentration of sawdust or similar material is added, this burns out when they are fired creating lots of air pockets for insulation. Insulating bricks are softer and lighter than the solid bricks and nearly all the heat goes into your project rather than heating several pounds of bricks.

Your bricks look like fire bricks.

|

|

|

|

Post by 1dave on Jan 9, 2014 15:03:23 GMT -5

We used a lot of "fire bricks" in the steel mill furnaces. They were high in cristobalite (very high temperature quartz) so they could take the heat.

|

|

|

|

Post by Pat on Jan 14, 2014 14:28:38 GMT -5

I never knew there were so many different kinds of bricks. I used to think a brick was a brick.

I'm not going to cut up my three new bricks with the words on them, now that I know their histories. They will be added to our brick path system. I appreciate all the information.

|

|

snuffy

Cave Dweller

Member since May 2009

Posts: 4,319

|

Post by snuffy on Jan 14, 2014 14:59:49 GMT -5

I never knew there were so many different kinds of bricks. I used to think a brick was a brick. I'm not going to cut up my three new bricks with the words on them, now that I know their histories. They will be added to our brick path system. I appreciate all the information. One of the most unusual bricks I've seen has "Don't spit on sidewalk" stamped on it.They placed one every so often when the sidewalks were brick,a health campaign during a tuberculosis outbreak.A lady in town we did a job for had one.  snuffy |

|

|

|

Post by radio on Jan 14, 2014 19:26:01 GMT -5

Firebricks are made from fireclay. (duh). Fireclay is a type of clay with high Aluminium Oxides which allow it to be used in high temperature environments (Furnaces and Kilns) without melting. Firebricks are always a light color. For jewellery making you are better of with insulating bricks, same stuff just that when they are made a high concentration of sawdust or similar material is added, this burns out when they are fired creating lots of air pockets for insulation. Insulating bricks are softer and lighter than the solid bricks and nearly all the heat goes into your project rather than heating several pounds of bricks. Your bricks look like fire bricks. The insulating bricks work awesome for soldering. When the surface gets uneven or pitted from use, take it outside and scrub it on the sidewalk a few times to resurface it. I like them because I can use pins to hold delicate work in place. They also last a lot longer than charcoal, or at least they do for me |

|

|

|

Post by 1dave on Jan 14, 2014 20:52:54 GMT -5

Something weird is going on with this site!

Notice there are now 18 replies and only 6 views? Not possible.

Somehow when something is edited the count drops back to zero.

|

|