|

|

Post by radio on Feb 22, 2017 20:13:20 GMT -5

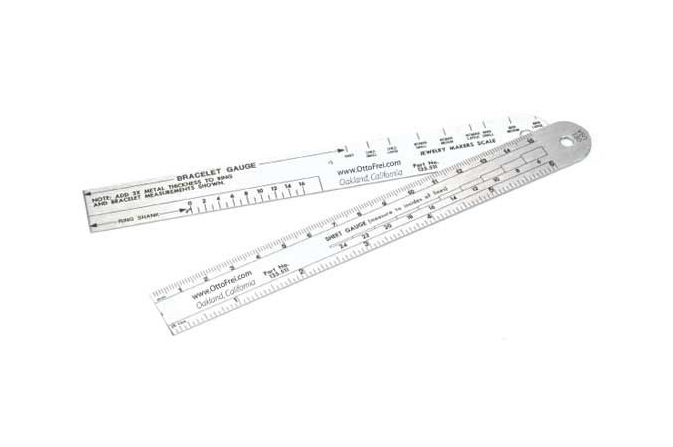

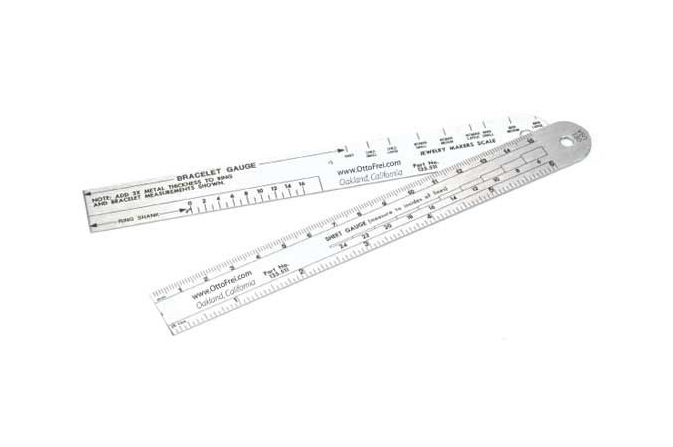

All of us who work with metals have a few things on our bench that we take for granted, but not everyone might know about. Post up your handy dandy items you would be lost without.  There are many ways to measure for ring shanks and bracelets, but by far the best method I have found is a jewelers ruler. They are hard to find, but Ottofrei and Raytech both make them. As a bonus, they also have a metal thickness from 6 to 24 gauge.  |

|

|

|

Post by rockjunquie on Feb 22, 2017 20:29:22 GMT -5

Never seen a jeweler's rule before. How do you use it, or is self explanatory? I can't make out all of it.

|

|

|

|

Post by radio on Feb 22, 2017 20:55:53 GMT -5

Never seen a jeweler's rule before. How do you use it, or is self explanatory? I can't make out all of it. It is a 6 inch ruler on one side with measurements in Millimeters also. On the other side is a scale for measuring out metal for ring shanks as well as bracelets. I tried and tried to find a better pic, but had to settle for a link hoping it would show enough detail www.ottofrei.com/Store/Dividers-Squares-Rulers-Wire-Drill-Degree-Gauges/Jewelers-Rule-Otto-Frei-Jewelry-Makers-Scale.htmlwww.silversupplies.com/catalog/tools/measuring/Rio has one, but it is plastic and not worth the postage even if it took only one stamp  for measuring metal for a shank, find your customers size with a ring gauge, then lay the metal for the shank on the ruler and mark at the needed size. Be sure and add one and a half times the thickness of the metal to the actual measurement. for split shanks that will be soldered to base of a bezel setting, use the exact measurement, or even subtract one size. I'm not a fan of soldering a bezel mount on a completely circular ring shank. There should be a decent gap between the ends of the shank where it is soldered to the base |

|

|

|

Post by rockjunquie on Feb 22, 2017 21:12:45 GMT -5

Thank you, radio. Makes a little more sense now.  |

|

|

|

Post by Pat on Feb 22, 2017 21:22:03 GMT -5

Interesting topic. I have a few. Will study your ruler, too.

|

|

|

|

Post by spiceman on Feb 22, 2017 22:18:10 GMT -5

A dremel tool does everything...

It even stops working when rock dust is sucked in the air vents.:(

|

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Feb 22, 2017 23:24:38 GMT -5

That's an interesting ruler Arlen. I'll have to look them up. I can see how that would simplify things immensely!

|

|

|

|

Post by Pat on Feb 22, 2017 23:31:39 GMT -5

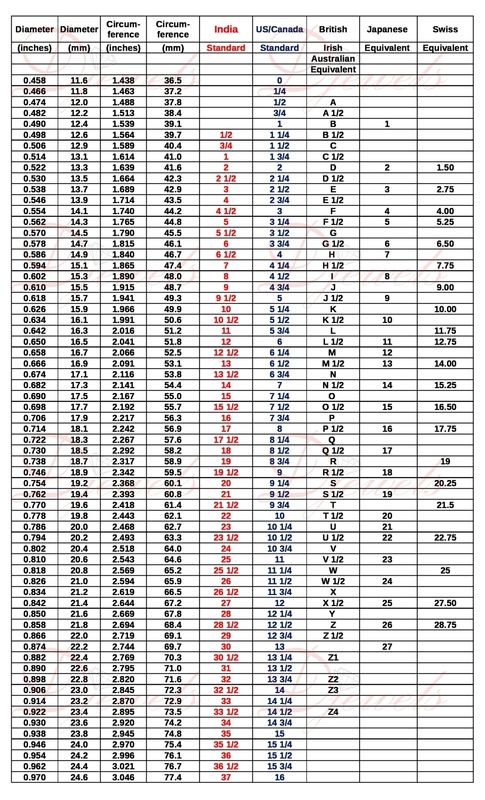

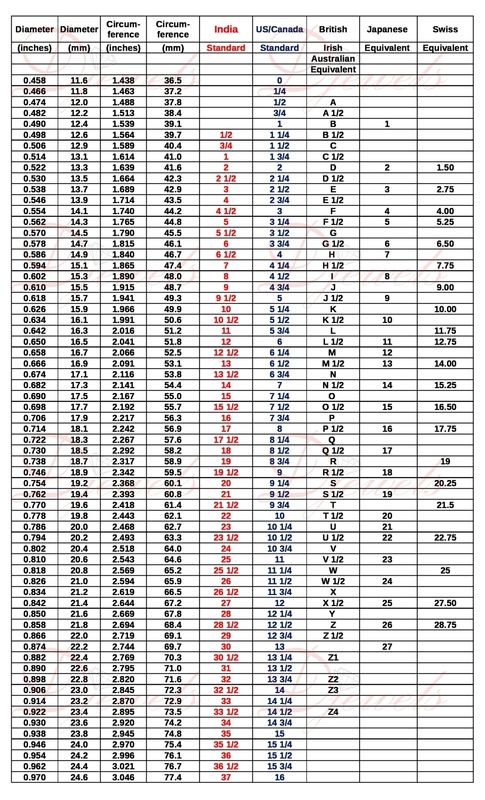

I have a chart that might give the same information as the ruler.

Ex: ring size 4.5 is 2". That's the only one I remember. Gives it in mm also.

|

|

|

|

Post by radio on Feb 23, 2017 7:48:15 GMT -5

I have a chart that might give the same information as the ruler. Ex: ring size 4.5 is 2". That's the only one I remember. Gives it in mm also. An abundance of charts are available from the simple to the absurd. Measurements in millimeters are easier to comprehend than deciphering thousandths of an inch and having the ruler with ring sizes already engraved on it greatly simplifies the process. if I have a custom, non standard size to make where size is critical, I usually cut the material then shape it around a ring mandrel to confirm it is correct before soldering. It is very common for me to have customers with arthritic fingers that present challenges in sizing, so I try to make the ring as small as possible fitting over the knuckle as once it is past there, it becomes very loose on the finger. This often involves 1/4 sizes and is a royal pain, but customers are always pleased someone goes to the length to get the best possible fit.   |

|

zekesman

Cave Dweller

Member since May 2016

Posts: 637

|

Post by zekesman on Feb 23, 2017 15:06:37 GMT -5

I always make my ring shanks about 1/4 size small and stretch them to size on a mandrel to work harden them.

|

|

|

|

Post by Pat on Feb 23, 2017 15:42:08 GMT -5

My favorite bench tool works for smithing and for rock carving. I can use both hands to manipulate the work. The small vise in the background is also very handy. Again, I can use both hands.  IMG_1570 IMG_1570 by Pat, on Flickr Front view of same tool. Foredom makes this. I've seen a similar device by Dremel; I think it suctions onto the workbench  IMG_1574 IMG_1574 by Pat, on Flickr |

|

|

|

Post by rockjunquie on Feb 23, 2017 18:10:51 GMT -5

My favorite bench tool works for smithing and for rock carving. I can use both hands to manipulate the work. The small vise in the background is also very handy. Again, I can use both hands. IMG_1570 by Pat, on Flickr Front view of same tool. Foredom makes this. I've seen a similar device by Dremel; I think it suctions onto the workbench IMG_1574 by Pat, on Flickr I have one of those foredom vices. Don't tell DH because he got it for me for my birthday (tools are a tradition now), but I never use it because I can't clamp it to my table. I don't even know where it is. |

|

|

|

Post by rockjunquie on Feb 23, 2017 18:15:38 GMT -5

I didn't think I would like them so much, but DH also got me the arms that attach to the foredom pole. I have 2 shelves and one that holds mandrels with tools on them. In my space, these are are essential to my work flow. I have another, but it won't fit. He got me the flip light that goes with it, but it turned out to be too big and we had to return it.

And, oddly, I find that I use a burnishers an awful lot. But maybe that's because of what I have been doing. I haven't actually soldered in a long time. (I should change that.)

|

|

|

|

Post by toiv0 on Feb 25, 2017 16:18:30 GMT -5

I love this little drill press, but the tool I can't do without is the shear. I hate cutting with the sissors or hand shears.   |

|

|

|

Post by Pat on Feb 25, 2017 18:55:05 GMT -5

toiv0. We have a much smaller shearer. It is a big help. Re hand shears: have you tried Joyce Chen shears? Very good, and with hand shears you can cut curves.

|

|

|

|

Post by toiv0 on Feb 25, 2017 19:50:31 GMT -5

toiv0 . We have a much smaller shearer. It is a big help. Re hand shears: have you tried Joyce Chen shears? Very good, and with hand shears you can cut curves. I havent heard of them, I just wack away with the big shear and saw when I need to go around a corner...haha. Call me lazy |

|

|

|

Post by radio on Feb 26, 2017 18:57:48 GMT -5

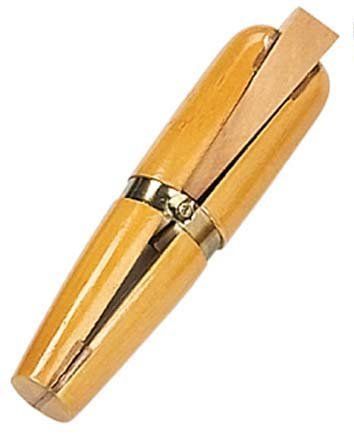

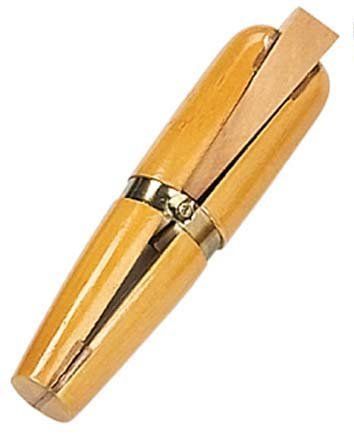

Another little gem I would be reluctant to do without. A hand vise is indispensable for twisting lengths of wire chucked in a drill as well as a multitude of other tasks  |

|

|

|

Post by radio on Feb 26, 2017 19:06:26 GMT -5

And another very useful bench tool is a ring clamp. I use this a LOT for cutting ring shanks needing resized.  |

|

gemfeller

Cave Dweller

Member since June 2011

Posts: 4,059

|

Post by gemfeller on Feb 26, 2017 20:53:23 GMT -5

Yep, it's exactly what it looks like: a common hardware store corner bracket screwed to a piece of wood. But if you've ever wished you had a 3rd hand when forming a bezel strip around a stone and marking it, this is the answer. I drilled a couple of small holes through the board and into my bench top so I can fasten it into place temporarily on the bench with some dropped-in nails. Arrange it so the inner part of the "L" is facing you. When you have the bezel wrapped part way around the stone, push the stone and bezel against the corner of the "L" to keep it secure while you complete the wrap and mark it for cutting. Simple, but it's saved me a lot of frustration (and mismarked bezels) over the years.  |

|

|

|

Post by Pat on Feb 26, 2017 21:16:32 GMT -5

gemfeller. I have that bracket screwed onto my workbench also. It is a help and works better than double stick tape.

|

|