Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 13, 2017 20:04:34 GMT -5

Does anyone here work with pneumatics? Need a simple circuit designed.

Know anybody?

Help! Need to retrofit an autofeed

|

|

|

|

Post by toiv0 on May 13, 2017 20:59:57 GMT -5

the auto feed is air? I guess I have never seen an air driven rock carraige.

|

|

|

|

Post by wigglinrocks on May 13, 2017 21:11:31 GMT -5

I'll see if I can get you a diagram . A friend has a 24" with air or water feed . It is currently set up for water but he is switching it back to air . Unfortunately , I won't be able to help you for a week or so . He might even have the manual yet .

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 13, 2017 21:28:14 GMT -5

the auto feed is air? I guess I have never seen an air driven rock carraige. Pneumatics less expensive and more flexible than hydraulics. Driven by a CO2 bottle or cheap compressor. We do not need the power of hydraulics. Even with gas we can push the rock too fast and destroy a blade. Imagine a slab saw that slabs at the rate of the cut. Instead of cut at the rate of the saw. Then returns the carriage to zero, shutting off the blade. Or more.... Just because you never saw it; doesn't mean it shouldn't be built! |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 13, 2017 22:54:08 GMT -5

I'll see if I can get you a diagram . A friend has a 24" with air or water feed . It is currently set up for water but he is switching it back to air . Unfortunately , I won't be able to help you for a week or so . He might even have the manual yet . Awesome! Thank you!! |

|

|

|

Post by wigglinrocks on May 13, 2017 23:17:58 GMT -5

I'll see if I can get you a diagram . A friend has a 24" with air or water feed . It is currently set up for water but he is switching it back to air . Unfortunately , I won't be able to help you for a week or so . He might even have the manual yet . Awesome! Thank you!! My forgetter is working real good but I will try to remember to ask him when he gets back in town . We were just talking about the feed the other day when I took a motor over to him for the saw . If the saw came with a manual , he would probably have it . |

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 13, 2017 23:22:01 GMT -5

Pneumatics have myriad valves. Many allow pressure control, shutoff/return/shutoff control...

And many other cool shit.

Deciding what valve to use and how to set it up is the conundrum. Two way cylinders are simple. It's the other stuff....

|

|

|

|

Post by wigglinrocks on May 13, 2017 23:33:15 GMT -5

I'll get ya any specs I can to help ease the conundrum . I should have been paying more attention when he was spewing out all the technical jargon about the saw .

|

|

|

|

Post by Rockoonz on May 13, 2017 23:54:19 GMT -5

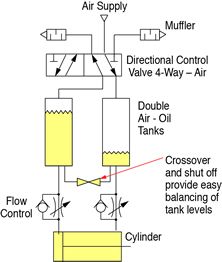

Air over oil is your ticket, My ROC 18" saw works that way.

Pneumatics are great in applications where it's no big deal if things bounce a little.

not so with rock saws. The diagram for both is identical, except for the two reservoirs.

The flow control that serves as a speed control, the directional control lever and the pressure regulator,

are the controls. An auto shut off is not advisable unless you can devise something that will shut off the feed

pressure and bleed it off a few seconds before stopping the blade. That is where an actual hydraulic pump is better,

especially a VW power steering pump running off the arbor shaft like the saws that J2B2 runs.

Did I mention my air over oil hydraulic saw is for sale?

|

|

|

|

Post by Rockoonz on May 14, 2017 0:32:42 GMT -5

Here's the air over oil diagram. Eliminate the tanks and you have pneumatic... I can get you part numbers for your manual lever control valve and speed control valve. Also you only need one speed control, you want a full speed return  |

|

notjustone

spending too much on rocks

Member since January 2017

Posts: 426

|

Post by notjustone on May 14, 2017 0:42:30 GMT -5

Air over oil is your ticket, My ROC 18" saw works that way. Pneumatics are great in applications where it's no big deal if things bounce a little. not so with rock saws. The diagram for both is identical, except for the two reservoirs. The flow control that serves as a speed control, the directional control lever and the pressure regulator, are the controls. An auto shut off is not advisable unless you can devise something that will shut off the feed pressure and bleed it off a few seconds before stopping the blade. That is where an actual hydraulic pump is better, especially a VW power steering pump running off the arbor shaft like the saws that J2B2 runs. Did I mention my air over oil hydraulic saw is for sale? I agree with rockoonz air compresses and gives things a spring effect. |

|

mikeinsjc

spending too much on rocks

Member since June 2010

Posts: 329

|

Post by mikeinsjc on May 15, 2017 9:34:40 GMT -5

rockoonz,

I too am interested in a hydraulic system, as I have an old Frantom 36" saw. The carriage is a beast, so I am looking to fit a hydraulic feed and return.

My first thought was to not reinvent the wheel, so I contacted Diamond Pacific about purchasing the components from them, as their 36 uses such a system. I thought if I could see their 36 in the showroom I could retrofit their system onto my saw. Problem is they build to order on the big saws and never have one in stock.

I'm sure this isn't rocket science, but I'm too old and impatient to undertake assembling a custom system and debugging it. I will start a separate thread inquiring about anyone using a factory-equipped hydraulic-fed saw.

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 15, 2017 12:55:26 GMT -5

Rockoonz Lee what do you mean about the bounce in pneumatics? What and where is this action? I get compressed air is a spring. I can't visualize how this is detrimental. I would be grateful if you would describe this issue. Thank you

|

|

mikeinsjc

spending too much on rocks

Member since June 2010

Posts: 329

|

Post by mikeinsjc on May 15, 2017 13:59:57 GMT -5

shotgunner,

my guess is the system doesn't tend to move continously. I would think there is a reasonable amount of static friction in the cylinder, and the pressure has to build up enough to overcome that, and the carriage moves in jumps. This is one of my reservations about trying to build my own. As slow as a saw carriage moves, its hard for me to believe there is a hydraulic or pneumatic system that can smoothly feed at that slow a rate. But I don't know anything about such systems either.

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on May 15, 2017 14:52:26 GMT -5

shotgunner, my guess is the system doesn't tend to move continously. I would think there is a reasonable amount of static friction in the cylinder, and the pressure has to build up enough to overcome that, and the carriage moves in jumps. This is one of my reservations about trying to build my own. As slow as a saw carriage moves, its hard for me to believe there is a hydraulic or pneumatic system that can smoothly feed at that slow a rate. But I don't know anything about such systems either. We have hydraulic feed at class. We have a set line in the broken pressure gauge to say "just right". Larger stones take longer smaller ones go faster. But, the cut speed is how fast the rock moves over the blade. So smaller agates can do 3-4" per minute. The push is slow and steady and always advancing as fast as the blade can cut. I'm thinking about the power steering pump concept. I like it. A lot. Have to figger out how to connect to the machine. Lee how does j2b2 connect the pump tot he saw? |

|

|

|

Post by MrP on May 15, 2017 19:41:21 GMT -5

@shotgunner here is a picture of my 20" saw using air for the feed. The rectangle part, middle left on the front, is a set of jaws that open to accept a 1/4" all thread rod that I use to start the feed. I start the feed with the rod to get the blade started into the stone then put the air to the feed.

The air cylinder is just a one way cylinder. There was a PVC cylinder feed by water when I got the saw. The cylinder is 1 1/2".

Simple regulator to limit input air, pressure gauge to know where you are at, valve on right is closed to give cylinder pressure and open to allow feed to be pulled back, center valve to feed pressure to cylinder.

I have cut a 6 X 9 piece of a picture sandstone, that was very hard for sandstone, in under 3 minutes with a perfect cut........................MrP

|

|

|

|

Post by wigglinrocks on May 15, 2017 22:30:25 GMT -5

@shotgunner here is a picture of my 20" saw using air for the feed. The rectangle part, middle left on the front, is a set of jaws that open to accept a 1/4" all thread rod that I use to start the feed. I start the feed with the rod to get the blade started into the stone then put the air to the feed.

The air cylinder is just a one way cylinder. There was a PVC cylinder feed by water when I got the saw. The cylinder is 1 1/2".

Simple regulator to limit input air, pressure gauge to know where you are at, valve on right is closed to give cylinder pressure and open to allow feed to be pulled back, center valve to feed pressure to cylinder.

I have cut a 6 X 9 piece of a picture sandstone, that was very hard for sandstone, in under 3 minutes with a perfect cut........................MrP

Just curios , was that saw made in Minneapolis ? Looks like the one I mentioned earlier . |

|

|

|

Post by Rockoonz on May 15, 2017 23:26:31 GMT -5

Rockoonz Lee what do you mean about the bounce in pneumatics? What and where is this action? I get compressed air is a spring. I can't visualize how this is detrimental. I would be grateful if you would describe this issue. Thank you Air is very compressible, you can fit a room full unto the tank on a divers back. With oil, on the other hand pressure doesn't change the volume very much. You could use air, but you need something to dampen the action. The Magnum Hydro saw that the club used to have had a regular screw feed with air assist, the screw set the cut rate and the air was there when needed. Never needed it. |

|

|

|

Post by Rockoonz on May 15, 2017 23:37:36 GMT -5

On closer examination MrP seems to have a magnum hydro. Can't mistake that vice, have you ever used the built in slab grabber edge? If it's like the one I fought/maintained for the club the side opposite the arbor flexes a lot and makes for lots of saw lines, my fix was to fabricate a piece to bridge the gap and in made a lot better cuts after that. |

|

|

|

Post by Rockoonz on May 15, 2017 23:45:48 GMT -5

Lee how does j2b2 connect the pump to the saw? The arbors have 2 pulleys and one of them runs a 2nd belt to the pump, that is also mounted under the saw plumbed like the diagram I supplied, but only one oil tank. Downside is the blade is turning while the vice is brought back, Not a show stopper but the reason I prefer screw feeds. |

|