|

|

Post by Drummond Island Rocks on May 13, 2018 19:28:14 GMT -5

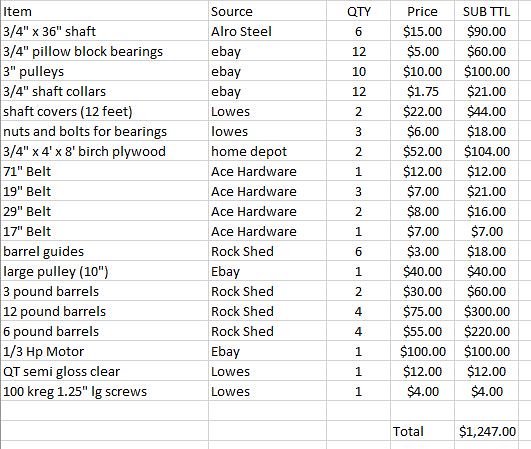

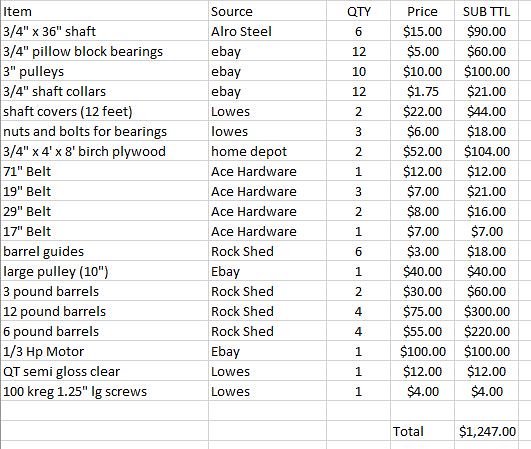

Thanks. $1,300 plus labor and shipping. Still interested? Over half of that cost is just for the barrels. The rubber hose always does that when new. They will eventually wear themselves round. It really is not an issue though. I ran it for a few hours and the barrels did not drift. There will be rollers installed at each end of each row soon. That's next on my to do list. Chuck I'm ok with that lol! I have 1/2 those barrels already, just need a few more lol. I have a Kreg, maybe just share the details (I'll buy?) and I'll try my hand at making one someday. I did not make any build prints. I just had my laptop in the garage and took measurements right from CAD as I was making cuts. This is the generic stock list. The listed prices do not include shipping for purchased items. I am sure shipping for four 12 pound, 4 six pound barrels and the 6 steel shafts would add a good amount. I still need to order my new motor. I have the old one on right now for testing.  Chuck |

|

saxplayer

fully equipped rock polisher

Member since March 2018

Posts: 1,327

|

Post by saxplayer on May 13, 2018 20:16:52 GMT -5

Thank you!

|

|

|

|

Post by Drummond Island Rocks on May 13, 2018 20:17:24 GMT -5

|

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on May 13, 2018 22:26:25 GMT -5

Like a fine Swiss watch. Edit: I tagged Jeannie earlier in the thread. She thinks I can build stuff. I wanted her to see the real deal. Chuck, I am humbled. Job well done. Would you share the roller wheel you will be using? My tumbler ruins them in 36 hours and barrel drift is an issue for me. Drummond Island Rocks |

|

|

|

Post by TheRock on May 14, 2018 0:33:23 GMT -5

Nice Piece of Engineering!

|

|

|

|

Post by Drummond Island Rocks on May 14, 2018 9:13:21 GMT -5

Like a fine Swiss watch. Edit: I tagged Jeannie earlier in the thread. She thinks I can build stuff. I wanted her to see the real deal. Chuck, I am humbled. Job well done. Would you share the roller wheel you will be using? My tumbler ruins them in 36 hours and barrel drift is an issue for me. Drummond Island RocksScott, With your design mounting the bearings vertical that allowed perfect spacing between the shafts but then the vertical mounting slots allow a bunch of up down adjustment. My horizontal mount means perfect flat across but then I needed to make a jig that spaced every set of bars the same distance at both ends and parallel to the frame. Kind of a catch 22 on which way to mount them. I had about 6 different designs going for my tooling cartridge portion and one of them was vertical. I just added jig that I would have used to insure the shafts were all the same height before tightening the bearing bolts. The jig is the orange piece. Notched to go around the other shafts. I would make two of those to place at each end then tighten those bolts and move them to the other side and repeat. After the top row is done you just cut them shorter and shorter for each row.  As for my rollers. If I could choose one they would already be done. I used the lortone barrel guides last time and I liked them because there's no moving parts and nothing to wear out. With those you just have to be more careful and remember to lift the barrel up and not just yank it forward. While in the garage last week a came across a couple extra garage door rollers and those caught my eye for a good and easy solution. I bought 6 just in case I decide to go that way. I bought standard ones at the hardware store but I actually seen some on ebay that had bearings in them. Lortone guide mock up  Door roller mock up (I did not mount and run it with this. The marks on the lid were already there from a previous owner of the barrel I guess)  Chuck |

|

|

|

Post by rockjunquie on May 14, 2018 9:53:21 GMT -5

You never fail to impress me.  Give me a holler when you think this thread has run it's course and I will enshrine it for you. Lots of great info. |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on May 14, 2018 10:16:55 GMT -5

My vertical spacing method does allow for left right cant. I solved that with drilling all holes for thr bearings the same time. I'm level as far as the frame is concerned. I'm not level due to danged garage floor! I suppose I could put leveling feet on it. Garage door rollers..... Hmmmmm..... Due you suppose rollers must be mounted at the circumference? I was looking at rollerblade wheels/bearings. I am using pvc pipe barrels. Drummond Island Rocks |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on May 14, 2018 10:20:40 GMT -5

Chuck, was that all one sheet of plywood?

|

|

|

|

Post by Drummond Island Rocks on May 14, 2018 10:28:23 GMT -5

Chuck, was that all one sheet of plywood? Everything I have posted to date has been one sheet of 3/4 birch plywood and one 8 ft. long 2x4. That left me enough to create the stiles and rails for shaker style doors. I still need to purchase one sheet of 1/4" thick material for the back and door centers. The top was reused so that would add a bit more plywood if needed. Chuck |

|

|

|

Post by Drummond Island Rocks on May 14, 2018 12:20:49 GMT -5

Looking fantastic, want to build one for me? LOL!! Some of the barrels were rocking a bit, does that mean you have to adjust the distance between the rollers? To speed up the process of truing up the shaft covers I held a woodworking rasp against each roller. As an added bonus at really adds some bite to the rollers.  Chuck |

|

|

|

Post by aDave on May 14, 2018 12:53:24 GMT -5

Very nice Chuck Drummond Island Rocks. I'm glad I waited to go through the thread when it was nearly completed, as I didn't have to wait much on progress. The videos were great...thanks for sharing. |

|

|

|

Post by Drummond Island Rocks on May 14, 2018 12:57:13 GMT -5

For those who like details. Here is a picture I took while milling the set screw flats. Figuring out where all 47 set screws needed to go took some time. Milling the flats with an end mill and die grinder was way quicker then figuring out where they went. This step is not necessary but will come I think it will really come in handy for repair disassembly.  Chuck |

|

|

|

Post by Drummond Island Rocks on May 14, 2018 13:02:10 GMT -5

Just one more picture for today. Now if only I had 78 pounds of rocks that needed to be tumbled.  Chuck |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on May 14, 2018 13:17:57 GMT -5

Tumbler porn

(Admin edit - removed the missing photo)

|

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on May 14, 2018 13:26:24 GMT -5

Just one more picture for today. Now if only I had 78 pounds of rocks that needed to be tumbled. PM me your address. Ill send ya a box to help the cause. |

|

|

|

Post by Drummond Island Rocks on May 14, 2018 15:34:27 GMT -5

My vertical spacing method does allow for left right cant. I solved that with drilling all holes for thr bearings the same time. I'm level as far as the frame is concerned. I'm not level due to danged garage floor! I suppose I could put leveling feet on it. Garage door rollers..... Hmmmmm..... Due you suppose rollers must be mounted at the circumference? I was looking at rollerblade wheels/bearings. I am using pvc pipe barrels. Drummond Island RocksRoller blade wheels would work good. I was actually looking at my kids skateboards originally and thinking those wheels are made for the abuse of cement and have bearings. My build is a little too tight for the diameter of roller blade wheels but skate board wheels may have worked. Lots of options out there. I want to get it right the first time to avoid adding unnecessary holes later. Chuck |

|

|

|

Post by aDave on May 14, 2018 17:00:37 GMT -5

My vertical spacing method does allow for left right cant. I solved that with drilling all holes for thr bearings the same time. I'm level as far as the frame is concerned. I'm not level due to danged garage floor! I suppose I could put leveling feet on it. Garage door rollers..... Hmmmmm..... Due you suppose rollers must be mounted at the circumference? I was looking at rollerblade wheels/bearings. I am using pvc pipe barrels. Drummond Island Rocks Roller blade wheels would work good. I was actually looking at my kids skateboards originally and thinking those wheels are made for the abuse of cement and have bearings. My build is a little too tight for the diameter of roller blade wheels but skate board wheels may have worked. Lots of options out there. I want to get it right the first time to avoid adding unnecessary holes later. Chuck FWIW, I'm pretty sure that skateboard wheels are available in much smaller sizes than what we probably saw with our kids growing up, so there may be something close in size to the garage door rollers, NRG. |

|

NRG

fully equipped rock polisher

Member since February 2018

Posts: 1,688

|

Post by NRG on May 14, 2018 19:03:43 GMT -5

Roller blade wheels would work good. I was actually looking at my kids skateboards originally and thinking those wheels are made for the abuse of cement and have bearings. My build is a little too tight for the diameter of roller blade wheels but skate board wheels may have worked. Lots of options out there. I want to get it right the first time to avoid adding unnecessary holes later. Chuck FWIW, I'm pretty sure that skateboard wheels are available in much smaller sizes than what we probably saw with our kids growing up, so there may be something close in size to the garage door rollers, NRG. They are definitely harder and smaller than when i skated pools in the 70's and early 80's. |

|

|

|

Post by Drummond Island Rocks on May 14, 2018 19:14:23 GMT -5

FWIW, I'm pretty sure that skateboard wheels are available in much smaller sizes than what we probably saw with our kids growing up, so there may be something close in size to the garage door rollers, NRG. They are definitely harder and smaller than when i skated pools in the 70's and early 80's. My son is 13. He is ordering all the parts tonight to build a new board. The wheels he showed me were $40 and the bearings were another $35. They are 53mm diameter wheels. The board he picked out is a Johhny Cash edition. I told him I thought that was cool. He replied with "I'll just cover up all the Johnny cash stuff with skate stickers". UGH He did tell me that his indoor board and outdoor boards use two different diameter and two different hardness of wheels. Way more technical then the early 80's when I used a skateboard as a mode of transportation. Chuck |

|