|

|

Post by Woodyrock on Jan 15, 2010 23:14:13 GMT -5

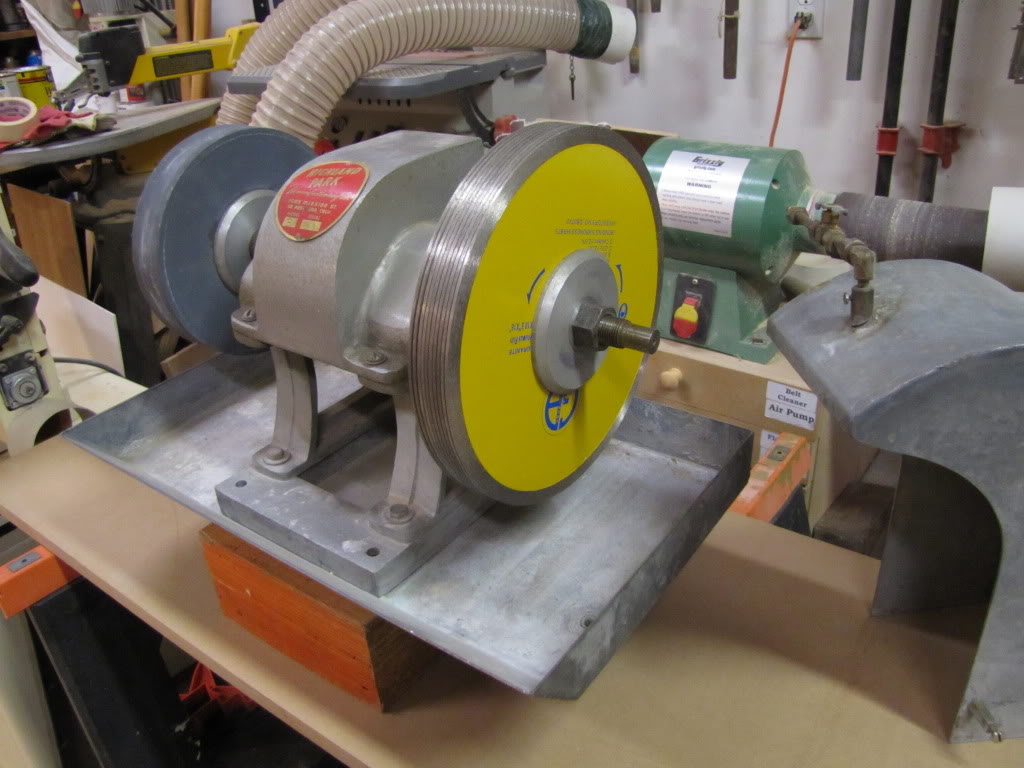

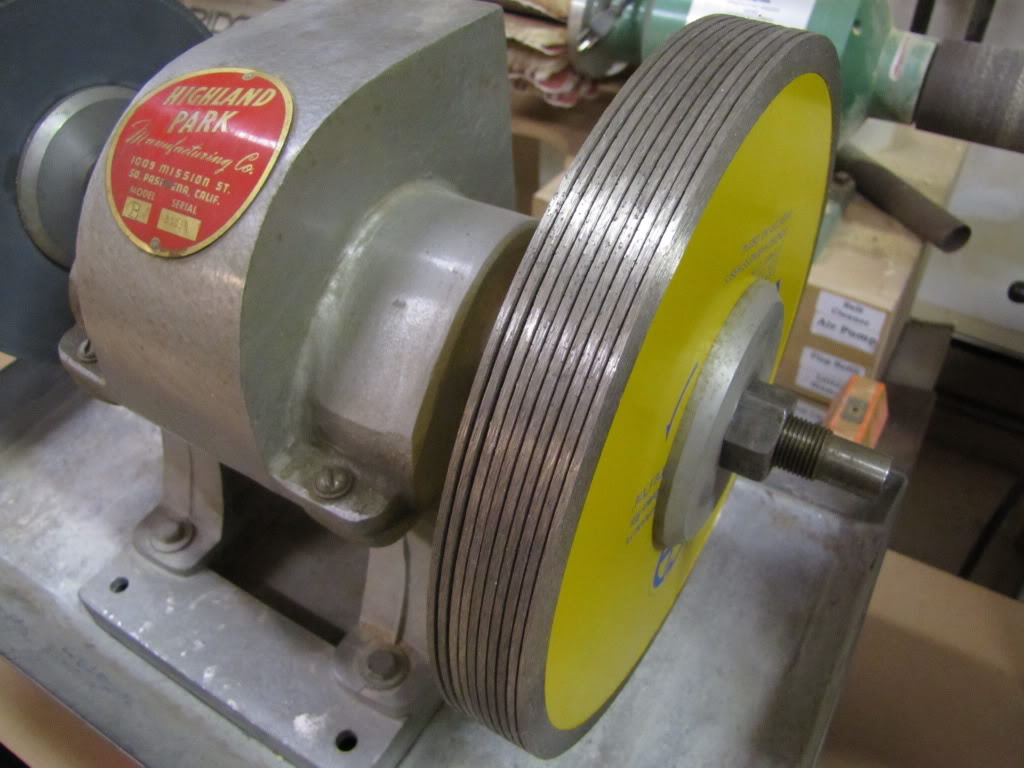

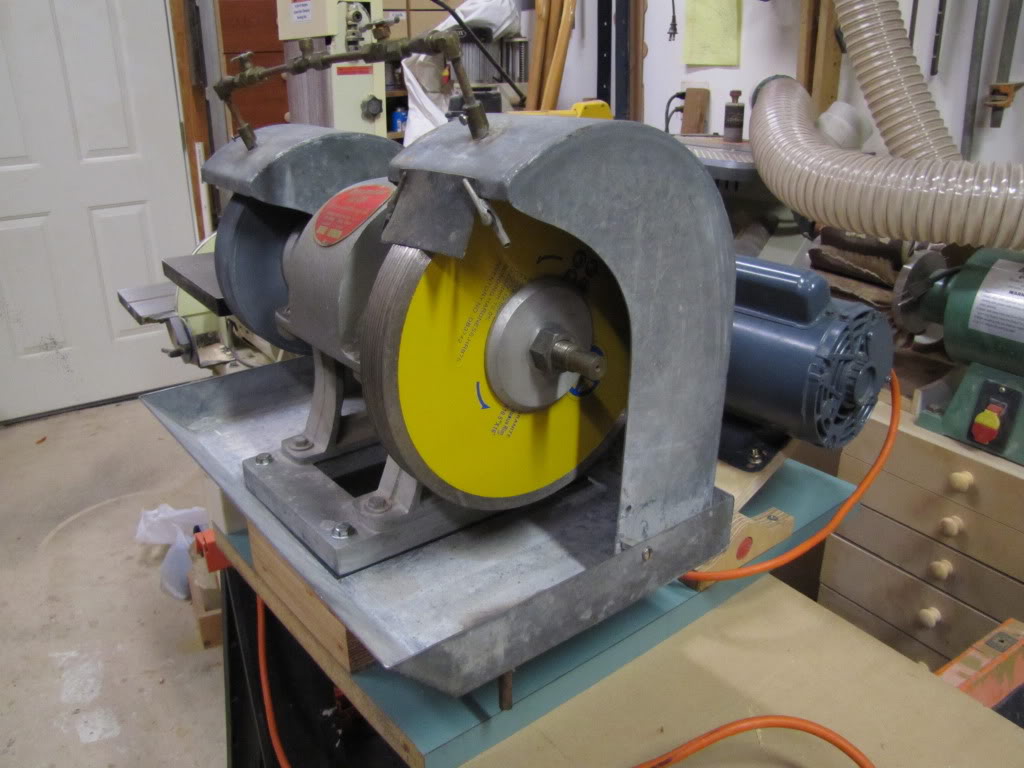

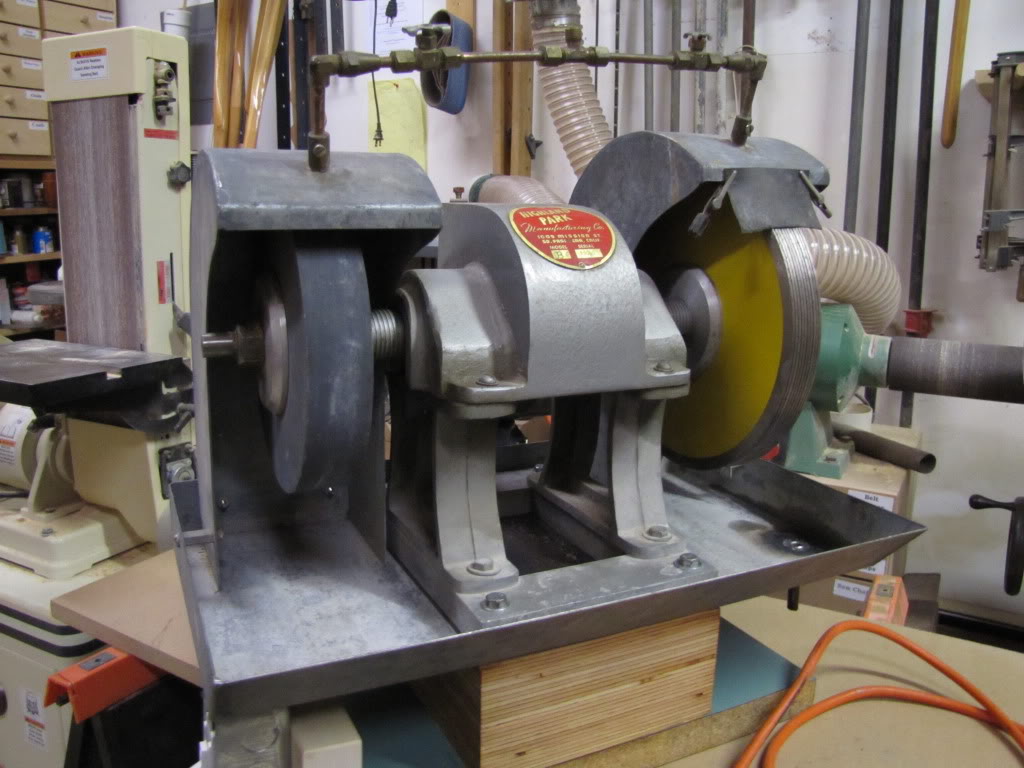

Here is the latest project, and something I have toyed with building for about two years now. Like everbody else, we are hard on the coarsw wheel, so this should save the first wheel. So, early this week, I ordered ten, ten inch saw blades from www.mcgillswarehouse.com for $9.00 something each having 12 carots of 40/60 mesh diamond. Between each blade is a washer made from formica to compensate for the cutting edgae thickness plus allow a wee bit of space between the blades. The blade stack is mounted on a Highland Park mandrel, with a 200 grit wheel on the other side. the whole thing will be driven with a 3/4 horse motor. I finished the super grinder todya, so here is what it looks like ready to roll. Now rolling, I put some stone to it today, and like others say, it eats agate like butter, and the end cut of lab even quicker. I hand held the close ups but you can still see what this blade stack does to agate, and basically one pass. It is much quieter than I thought it would be, but it does throw water. Woody The super grinder  A close up  Finished ..grinder end  The whole rig  First preforms ground  A close up  |

|

WarrenA

fully equipped rock polisher

Member since November 2003

Posts: 1,530

|

Post by WarrenA on Jan 16, 2010 0:03:38 GMT -5

are you going to cool the wheels with water? You will have to be careful not to go to fast and burn through the rock. good work it should save you a lot of time grinding

|

|

textiger

freely admits to licking rocks

Member since May 2005

Posts: 946

|

Post by textiger on Jan 16, 2010 0:39:19 GMT -5

The Houston Gem and Mineral Society has one. It's awesome. Great for quickly trimming away excess to reach the shape you want.

|

|

|

|

Post by Woodyrock on Jan 16, 2010 1:18:43 GMT -5

The Houston Gem and Mineral Society has an article on building a super grinder, I did have a look at their article after I started building this, Here is a link to that article. www.hgms.org/Articles/SuperGrinder.htmlOne thing I did not think of was the chip deflector under the wheel their design uses. Actually, I probably would not have thought about doing something like that, but I will put one on my super grinder. You can see the water drip piping on the hood next to the grinder. There will also be a rubber flap riding on the blade stack to both spread the coolant water, and to minimise spray. Woody |

|

|

|

Post by Hard Rock Cafe on Jan 16, 2010 10:35:11 GMT -5

I've wanted to do this for some time, but won't get around to it for a while. Let us know how it works!

Chuck

|

|

|

|

Post by johnjsgems on Jan 16, 2010 11:11:28 GMT -5

The club where we used to live built on for a 10" Poly Arbor they had. I saw it three years old and used a lot for sphere preform grinding. It literally looked brand new still. The only bad thing was it was so noisy they had to put it outside with the slab saws. I don't remember what thickness spacers they used to keep the cores straight but someone told me they used the AOL free minute discs sent in the mail. Nice job on an indestructible grinder.

|

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,494

|

Post by Sabre52 on Jan 16, 2010 17:43:45 GMT -5

Wow that is an excellent idea, especially since the newer coarse diamond wheels don't seem to cut as well or last as long as they used to. That sucker you've built looks like it'd flat chop out preforms in a jiffy!.....Mel

|

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Jan 16, 2010 21:32:14 GMT -5

Sweet build Woody. I'd like to see a video of that thing eating some of your awesome rough!

Nate

|

|

blessed

spending too much on rocks

Member since January 2010

Posts: 329

|

Post by blessed on Jan 17, 2010 12:58:25 GMT -5

You do good worK Woody. I have startes building one also. It will have an 8 x 3 exact-spand one side with 7" tile saw blades no the other side. We have anouther common interest, wood. I am a retired woodcrafter. Keep them tumblers rolling. Blessed

|

|

|

|

Post by stoner on Jan 21, 2010 3:06:56 GMT -5

I've been using stacked blades on my grinder and they work great. It eats agate like it's sandstone! I get a lot chipping, but as long as I don't go too close to what I want to keep, no problem. It really saves wear on the coarse wheel.

|

|

|

|

Post by rockmanken on Jan 21, 2010 8:13:07 GMT -5

I have been using 6 - 6" blades on my 6" unit for a while now and it works great. Only difference is that I don't care if they dish, I have them all tight to each other and get no chipping. Eats the hardest agate like it is butter.

Ken

|

|

NDK

Cave Dweller

Member since January 2009

Posts: 9,440

|

Post by NDK on Jan 23, 2010 22:40:33 GMT -5

Nice preforms Woody. Man, that really eats those stones, doesn't it!

Nate

|

|

|

|

Post by Jack ( Yorkshire) on Feb 28, 2010 5:03:10 GMT -5

Hi I made one when this Idea came round from the Huston Gem club 3 or 4 years ago I made mine a bit smaller and didnt bother with the washers, (still slings water around though)  Yes it certainly eats agate and is amazing at this, and as you say saves the Sc wheel You got some Brilliant shapes There I send my Pre forms straight to the Vibe (220Grit) works out well Thanks for bringing this Idea up again its a winner Jack Yorkshire uk |

|

quartz

Cave Dweller  breakin' rocks in the hot sun

breakin' rocks in the hot sun

Member since February 2010

Posts: 3,359

|

Post by quartz on Mar 6, 2010 16:19:44 GMT -5

A nice job you've done there. A friend built one with 4 stacked concrete cutting wheels, it did a great job, but he said he had to hang on tight.

|

|

jimrbto

noticing nice landscape pebbles

Member since April 2007

Posts: 94

|

Post by jimrbto on Mar 7, 2010 5:09:27 GMT -5

Not to be a nit picker but something about the close-up photo of the blades bothered me, on closer inspection it appears as if the shaft in that unit is reversed. Could be a real problem as the left hand side is on the right, i.e. the threads on the right side are left hand threads and this could lead to the whole side, super grinder, coming off.

Jim

|

|

zarguy

fully equipped rock polisher

Cedar City, Utah - rockhound heaven!

Cedar City, Utah - rockhound heaven!

Member since December 2005

Posts: 1,791

|

Post by zarguy on Apr 24, 2010 23:35:06 GMT -5

Woody - Awesome tool!

Since those are 10" blades on an arbor meant for 8" wheels, did you make your own hood to accommodate the larger size? Those don't quite look like HP hoods.

If I could get that same blade in 8" I could make a supergrinder with a standard 8" arbor.

Lynn

|

|

meta7

starting to spend too much on rocks

Member since June 2010

Posts: 164

|

Post by meta7 on Sept 9, 2010 22:45:27 GMT -5

If my motor is only 1/2 HP, but I want to stick with 10" blades, would it work or would I have to lower the number of blades to 5-6?

Also, does anyone else have experience with not putting washers in between and thus the chipping does not occur?

Thanks.

AND, where can you find these cheap blades that have a 1" hole for a 1" arbor?

|

|

|

|

Post by Woodyrock on Sept 9, 2010 23:58:51 GMT -5

Lynn: I made the hoods by soldering sheet metal. When I made them, they were for eight inch wheels, so, I just raised the one for the super grinder an inch. It is fairly easy to solder up hoods with an acid fluxed lead solder. Meta: I buy the cheap blades from www.mcgillswarehouse.com they have a pretty good selection, and a chart that shows how much diamond, and the diamond hardness. I will eventually reduce the thickness of the shims I used between the blades to make a more solid surface, but the darned thing just works to god to bother messing with it. Woody |

|

meta7

starting to spend too much on rocks

Member since June 2010

Posts: 164

|

Post by meta7 on Sept 10, 2010 18:27:04 GMT -5

Woody,

Could you please give me the link for that chart that tells the grit and how much diamond for each blade?

Looks like everything is 5/8" or 1/2" shaft size?

Dave

|

|

|

|

Post by johnjsgems on Sept 10, 2010 22:07:13 GMT -5

You have to have the blades punched out to your shaft size. Someone told me he drilled his with a step drill and it worked ok. I have not tried it. You could use 7" tile blades if you want to stay under 8" hoods.

|

|