Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jun 7, 2013 22:26:35 GMT -5

I must know. Did you let that man out of the fireplace?? lol

It seems you are missing furniture. Did someone steal it?? b-)

The home looks very near completion. Congrats!

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 7, 2013 22:46:49 GMT -5

Snuffy, you're right, we make the EIFS the very same way: a first layer with fiberglass net, then the seccond layer (that's how our walls are now) and then a decorative paint or stucco. Scott, LOL! No, the man is out  The furniture is still in work (some of it) or in project (most of it). Adrian |

|

|

|

Post by helens on Jun 8, 2013 2:05:52 GMT -5

Bricks in the CEILING?! I've never seen that before...

Very neat to see the progress!!! I like the stonework in your fireplace too:).

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 8, 2013 7:05:17 GMT -5

Bricks in the CEILING?! I've never seen that before... Helen, I tried to build the basement in the style of the old cellars. If you scroll the page #21 of this thread, you'll see how it was built. It's not real brick, but I like it. Adrian |

|

|

|

Post by helens on Jun 8, 2013 8:15:15 GMT -5

Ahh... I see, brick veneer! It is lovely!! Mortar can come loose... I was wondering what would happen if 1 happened to come loose. A whole brick weighs like 10 lbs... a flying 10 lb brick dropping on glass or someone's head would be bad:). I thought maybe it was some special kind of mortar (like epoxy) that was stronger and stickier than regular mortar for the bricks overhead, orr some special kind of bricks (maybe triangular in the backside, that was anchored more solidly in the mortar so they couldn't fall out. I really like that look... the cask of amontillado comes to mind:P. Great winecellar!!

|

|

|

|

Post by kk on Jun 8, 2013 9:05:20 GMT -5

Has been a while since I dropped in here. And man your project has jumped eons ahead. Looks absolutely fantastic and your basement could be ready and converted into your workshop overnight.   |

|

|

|

Post by connrock on Jun 9, 2013 6:54:32 GMT -5

Hi Adrian,,,

Very good up-date!Everything is moving along soooo fast now and some finishing touches are just over the horizon!

The sliding gate must be very heavy,,,,does it move easily? My neighbor made his own out of wood but he is a REAL do-it-yourself guy and won't listen to anyone who tries to help him and maybe give him some ideas on how to do things.Now his gate is soooooo heavy and with his design for rollers.etc,,,it takes 2 small boys,,,,3 strong men and a jackass to open and close the gate! LOL

I don't know anything about mason work or cement work but I am very surprised to see the stucco(rendering) go onto the styropor!Even with the fiberglass I would think the stucco would just not stick very well???

Good idea to have a lot of electrical outlets in the basement!I have over 20 in my shop and it's still not enough! LOL The "womans workshop"(bathroom) could have 50 outlets and would need 50 more! LOL

Is the white tank in the loft an expansion tank for the heating system? You probably didn't think I would notice but I do see that empty wine bottle on the floor in the corner!Were you up there "tipping" a few?? LOL

Everything is coming along very well and I hope some day you can find those plumbers to come back and finish their work!

You can never find a plumber when you need one! LOL

connrock

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 9, 2013 11:17:52 GMT -5

Thank you Tom and Kurt! Tom, the gate is not as heavy as it looks, that bar is hollow (3 mm thick walls). It can be slid with ease. Me too, I was afraid about rendering the styropor, but there's a special material which adheres very good to the styropor. You're right, the white tank is the expansion tank for the liquid (antifreeze) running through the solar panels. And what a keen eye to spot that bottle in the background!!!  I suppose it's there since the crew was working in the loft to thermo-insulate it. It was cold back then and they probably needed some "anti freeze"  Adrian |

|

|

|

Post by connrock on Jun 10, 2013 7:46:50 GMT -5

Hi Adrian, The weight of the gate: The weight doesn't matter if the design is good! I've seen some very heavy equipment move with very little effort and although I didn't see this my dad did and told me about it,,,,, In 1945 the company I worked for used to build sugar mills.These sugar mills were built in a long fairly narrow building and one such mill was built that had 16 or 17 of the huge drives connected in sequence(a line).It took over 300 feet of the building to fit all of these drives in a line and a "wheel" was attached to the first (main) drive and a platform was built so the wheel could be reached with ease. The company had an "open house" where the public and news media was invited to see what was being built there. A little 9 year old girl turned the wheel on the main drive and everyone could see that the last drive in the line was turning with ease! It's ALL in the design and I am sure your gate was designed VERY well,,,,no matter how heavy it is! I'm surprised that the expansion tank doesn't have an "air vent" on top of it? Is the expansion tank connected to the entire heating system or only the solar panels? Please check on this before you finish that bottle of wine in the loft! I laughed when you tried to blame the workers for leaving it there! LOL  |

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 10, 2013 13:27:02 GMT -5

Hey, it was THEM!  There's an air vent right on top of the solar panels (the air vent was installed after I took the picture of the panels so it does not appear in the picture with the panels). Should the expansion vessel have another air vent too? The highest point is the top of the panels, not the expansion vessel. Adrian |

|

|

|

Post by connrock on Jun 15, 2013 9:01:21 GMT -5

Hi Adrian,,, NO,,there should not be an air vent on top of your expansion tank!!!I was WRONG to say that!!! My eyes were seeing your tank and my brain was thinking of a conventional" hot water heating system with a boiler!!!!! My "mouth" got ahead of my mind and I am VERY sorry! The way an expansion tank is designed,,,it has a rubber "bladder"(like a rubber tire tube) in it.The bottom of the tank has air in it and the top of the tank has water/antifreeze in it. There is an air valve at the bottom of the tank to put air into the "bladder" to create a small amount of "cushion" so that the water can expand and contract as it gets hotter and colder. In a "conventional" hot water heating system,,,,,one picture is worth 1000 words,,,  connrock |

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 17, 2013 14:44:41 GMT -5

Thanks Tom! This is pretty much the same what the plumber told me when I was asking him about the air vent. Not as detailed as you explained above, though.

Adrian

|

|

|

|

Post by talkingstones on Jun 19, 2013 7:27:26 GMT -5

Adrian, I love the fireplace! The stonework looks beautiful!!!! Love the details you've been putting in throughout... this is really going to be nice when you're done!!!

Cathy

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 23, 2013 7:39:43 GMT -5

|

|

|

|

Post by connrock on Jun 23, 2013 8:26:15 GMT -5

WOW,,,That hole in the ground a few months ago is turning into a real house now!

Everything is moving along very fast now and the finishing touches look great!

There was a lot of "out of position" welding on the balcony hand rail and that's not much fun to do!I hope you gave that worker some of the wine you hide up in the loft? LOL

I'm glad that you could finally drag those darn plumbers out of the tavern to come to finish their work! LOL

The parquet looks very nice!What kind of wood is it?Does the black "underlay" have some kind of adhesive on it?I'm not familiar on how this type of flooring is installed?

Thanks for the update Adrian and I hope everything goes well this coming week!

connrock

|

|

snuffy

Cave Dweller

Member since May 2009

Posts: 4,319

|

Post by snuffy on Jun 23, 2013 8:55:30 GMT -5

Adrian,I installed my flooring like that.I did it myself to save money.I was barely able to walk for 3 days,couldnt climb up on a stepladder at work! Never again! Looking good

snuffy

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jun 23, 2013 10:55:43 GMT -5

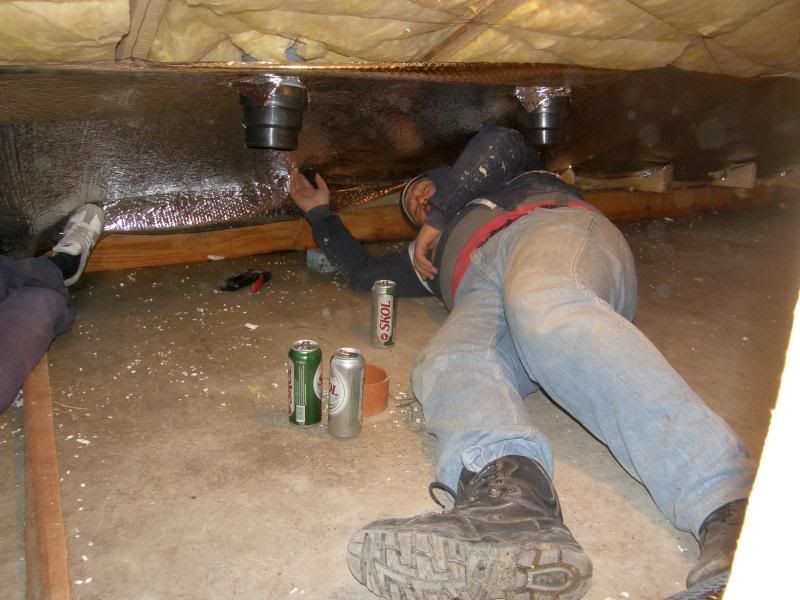

Tom, I was cleaning the loft and ... believe it or not (I'm pretty sure you won't  ), that one was the only bottle I found. It was empty. Again you won't believe me, but I don't know by whom.  Funny that you mentioned to give some wine to the welder: believe it or not, he would not accept a drop of wine: he is Adventist. This is why we took this pic of him, back when we were working in the loft. Some co-workers placed some beer cans next to him to look like he was drinking them and he's tired because of this  We keep joking about threatening him we'd go to his church to show this photo   That type of flooring is a fake parquet, we call it here "laminated parquet". It's in fact a sort of plywood with a plastic foil on top to imitate the look of wood. The black underlay is a 5 mm soft layer (kinda like styropor. This "parquet" is pretty resistant (it withstood to a scratch of a car key - that was the test before buying it) and it's easier to install compared to the real parquet. And also cheaper. It may not be the top choice for floor finishing, but our philosophy in building this home was to build as good as possible the elements which are impossible or very hard to modify when the house is done. That's why the structure is as sturdy as you know, the walls are thick, etc. Not the same standard to a parquet which could be replaced much more easily. Snuffy, it's not very easy to install this flooring, especially by yourself. There were times when they were working three in a row, to "marry" the parquet rows on the entire length of the row. Adrian |

|

|

|

Post by Bikerrandy on Jun 23, 2013 21:10:27 GMT -5

Beautiful work!! That house is built to higher standards than most of the houses over here. Yours is gonna be around for many generations  |

|

|

|

Post by connrock on Jun 24, 2013 7:30:49 GMT -5

Aha,,,,Now I understand why you have a "lift" going up to the loft!

MUCH easier to get alllllllll that wine and beer up there! LOL

I have heard of wine cellars but never a wine loft! LOL

I'm not an Adventist but I did quit drinking many years ago so me and the welder could stay "dry" together,,,,while the rest of you got "wet" up in the wine/beer loft!

Enjoy,,,,,have fun and good luck!

connrock

|

|

|

|

Post by helens on Jun 25, 2013 9:44:25 GMT -5

What's so wonderful about your step by step photos is that we get to see how houses are built in Europe, and how it's different from US building in materials and methods. Love it!!!

As it's closer to finished, bet you are more and more excited Adrian:)!

|

|