metalsmith

Cave Dweller

Member since October 2012

Posts: 1,537

|

Post by metalsmith on Nov 20, 2016 6:46:00 GMT -5

The water business is now set up, but haven't figured out how to attach the arm that holds the dop. Working on it. Eager to flip the switch : ) Its good to hear you're progressing. A picture could help me / others help you.  |

|

gemfeller

Cave Dweller

Member since June 2011

Posts: 4,059

|

Post by gemfeller on Nov 20, 2016 14:19:03 GMT -5

The water business is now set up, but haven't figured out how to attach the arm that holds the dop. Working on it. Eager to flip the switch : ) Since I know the machine you're using I could help you if I knew specifically what your problem is. If your manual is like mine, the illustration on page 2 shows the operation of the facet head. The dop is inserted through the hole in the bottom and the projecting key is aligned with the dop key. Then it's a simple matter of tightening down the dop lock nut until it's snug. Sometimes I give the lock nut a very gentle tightening with pliers because it can become loose during operation -- not too tight! Then set the desired angle on the protractor, turn the handwheel under the parallel platform (lily pad) to raise or lower it to the height needed, put the facet head (frog) on the lily pad and flip the switch (assuming you have a lap installed). I make sure the stone is higher than the lap to begin, and lower it incrementally as the cut proceeds until I'm at the right depth. Controlling depth of cut is the toughest part of faceting for me. But that's another subject for another time. Good luck and let me know whether the above covers the problem you're having. |

|

|

|

Post by Pat on Nov 20, 2016 14:48:57 GMT -5

metalsmith I've taken photos, and will post them today. Thanks for the encouragement. gemfeller thanks. I had done your suggestions in paragraph one. I didn't know about the extra tightening with pliers. My concern is putting the facet head (frog) on the lily pad. Seems like there ought to be a way to secure it. Seems like the dop would slide around on the lily pad. Does it get secured, or does the weight and angle of the frog hold it in place? Thanks for the details. I'll get photos up asap.

|

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Nov 20, 2016 15:28:36 GMT -5

There's a primative Youtube video posted online that shows the Raytech-Shaw machine handpiece being used.

And if a pair of pliers is having to be used to keep the dop nut tight then it's time to replace the nut. Either the treads are worn out in the nut or the threads are worn out on the dops. If it's the dops that are worn then replacing the nut with a new one with unworn threads will help.

Larry C.

|

|

|

|

Post by Pat on Nov 20, 2016 15:34:34 GMT -5

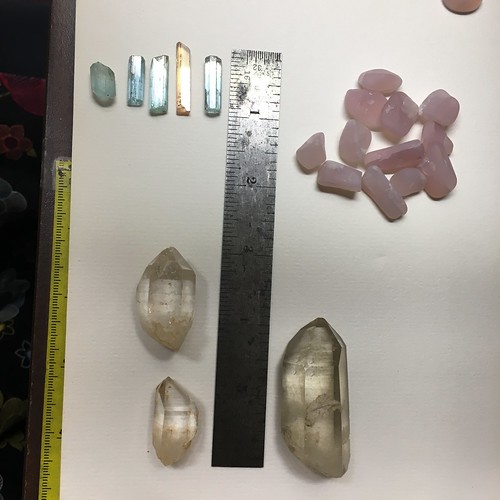

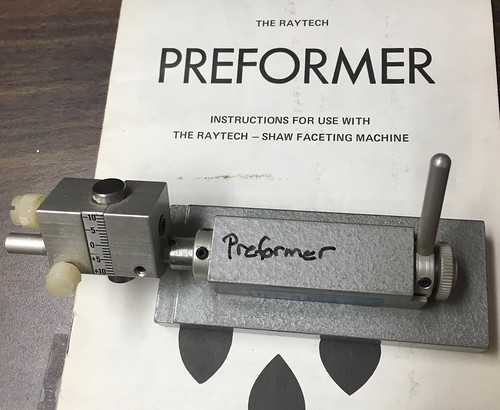

Photos of half-baked setup. 1- below is group shot of what I will facet.  IMG_1126 IMG_1126 by Pat, on Flickr -------- 2- quartz crystals to clean up  IMG_1127 IMG_1127 by Pat, on Flickr ---------- 3- various stick crystals to clean up  IMG_1128 IMG_1128 by Pat, on Flickr ------- 4- small (less than dime size) chalcedony to actually facet  IMG_1129 IMG_1129 by Pat, on Flickr ------- 5-Preformer. Want to check it out. Maybe preforming for faceting can be done on the facet machine.  fullsizeoutput_1448 fullsizeoutput_1448 by Pat, on Flickr ----- 6- Keyed dopsticks in various stages. I didn't do these.  fullsizeoutput_1446 fullsizeoutput_1446 by Pat, on Flickr ----- 7-faceting machine in bare bones condition  fullsizeoutput_144a fullsizeoutput_144a by Pat, on Flickr ------ 8-Frog randomly placed on lily pad. Don't know how yet.  fullsizeoutput_144c fullsizeoutput_144c by Pat, on Flickr -------- 9- High tech water system  IMG_1134 IMG_1134 by Pat, on Flickr -------- 10- Dop transfer jig. Looks like a good idea.  fullsizeoutput_1447 fullsizeoutput_1447 by Pat, on Flickr ------- 11- Do these items belong to the faceting machine?  fullsizeoutput_144b fullsizeoutput_144b by Pat, on Flickr 12- Another view of questionable items.  fullsizeoutput_144d fullsizeoutput_144d by Pat, on Flickr Next will be to add a disk, then decide which disks in what order, then preform (maybe use Preformer), dop, and hopefully be ready to flip that switch! |

|

gemfeller

Cave Dweller

Member since June 2011

Posts: 4,059

|

Post by gemfeller on Nov 20, 2016 15:49:08 GMT -5

There's a primative Youtube video posted online that shows the Raytech-Shaw machine handpiece being used. And if a pair of pliers is having to be used to keep the dop nut tight then it's time to replace the nut. Either the treads are worn out in the nut or the threads are worn out on the dops. If it's the dops that are worn then replacing the nut with a new one with unworn threads will help. Larry C. , that's really not the case in my situation. As a jeweler I operate on the "less is more" principle - never use sufficient force to cause damage. Maybe I was under-tightening the nut by hand but I noticed it loosening enough now and then to cause alignment problems. Now I just give it a very, very gentle squeeze with pliers to make sure it's firmly set. The nut's fine. |

|

|

|

Post by Pat on Nov 20, 2016 15:49:16 GMT -5

QuailRiver thanks. That was helpful. I see that the frog is not anchored to anything. The frog in the following video looks like what I have. In fact, I see that I need to hold onto the frog the entire time, so I don't need/shouldn't need to attach the frog to the lily pad in any way. doh! Whew!

|

|

metalsmith

Cave Dweller

Member since October 2012

Posts: 1,537

|

Post by metalsmith on Nov 20, 2016 15:53:39 GMT -5

Looks like a plug or a bore converter for a drain - and a rubber bung for stopping one. If there's no similar diameter pipes on the facetter (can't see it) then I can't see they belong, myself. Just to be safe, keep until proven not needed.

|

|

metalsmith

Cave Dweller

Member since October 2012

Posts: 1,537

|

Post by metalsmith on Nov 20, 2016 15:56:04 GMT -5

@qualriver thanks. That was helpful. I see that the frog is not anchored to anything. Now I've I'd what you mean by 'frog', yes, that is my understanding. The dop has to travel across the disk to prevent wear and keep exposing fresh disk as that immediately below the stone would fill with grounds. |

|

metalsmith

Cave Dweller

Member since October 2012

Posts: 1,537

|

Post by metalsmith on Nov 20, 2016 15:58:41 GMT -5

Next will be to add a disk, then decide which disks in what order, then preform (maybe use Preformer), dop, and hopefully be ready to flip that switch! Now that switch is positively itching ...  |

|

gemfeller

Cave Dweller

Member since June 2011

Posts: 4,059

|

Post by gemfeller on Nov 20, 2016 16:11:50 GMT -5

Pat , the handpiece is supposed to be moveable on the platform. This allows the entire lap surface to be used along with a few other benefits, such as being able to lift the entire handpiece to check progress on a facet. There's usually a "sweet spot" on a lap that's in perfect alignment with the platform. That's "home base" for checking your depth of cut, but it's important to use the entire surface so wear is even, just as it is on cabbing wheels. Lap surfaces are not perfectly flat as you'll quickly learn. I've never used the preformer but yes, it's designed to cut automatic preform shapes on your faceting machine. I don't recognize the parts in #12 as being part of the faceting machine; maybe they go with the performer. Check your manual. I notice the notch in your splash pan is turned toward the water spout. I think it's actually designed to allow space for the dop to align with the lap while you're preforming or cutting girdles at 90 degrees. It's different than mine so I'm not familiar with its operation. I had to cut a similar notch in the pan itself to get the dopped stone low enough to contact the lap when girdle-cutting. I McGyvered a patch to cover it during other operations to avoid getting wet. Looks like you have some great starter materials to work with.

|

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Nov 20, 2016 16:49:49 GMT -5

[/quote] QuailRiver, that's really not the case in my situation. As a jeweler I operate on the "less is more" principle - never use sufficient force to cause damage. Maybe I was under-tightening the nut by hand but I noticed it loosening enough now and then to cause alignment problems. Now I just give it a very, very gentle squeeze with pliers to make sure it's firmly set. The nut's fine. [/quote] I've cut many stones on several different Raytech-Shaw machines and don't recall ever having a hand tightened dop nut come loose while faceting. So I'm really not understanding the "less is more" principle being applied to using pliers to tighten a knurled nut on aluminum threads. But hey, to each their own!  Larry C. |

|

gemfeller

Cave Dweller

Member since June 2011

Posts: 4,059

|

Post by gemfeller on Nov 20, 2016 16:57:57 GMT -5

Quailriver: I'll drink to that last comment.

|

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Nov 20, 2016 17:02:45 GMT -5

The item to the right in your last photos is a tapered drive cone. Ultra-Tec and the old Seattle Fac-Ette machines used this type of drive cone and a beveled arbor platen in lieu of a belt and pulley drive system. The item at the bottom of the group looks like a brass ferrule like those used on the wooden handles of wood carving chisels and tools to help prevent the wood handle from splitting under stress during use. www.leevalley.com/US/wood/page.aspx?p=30021&cat=1,41504 Larry C. |

|

|

|

Post by orrum on Nov 20, 2016 20:59:19 GMT -5

One rule, one very important rule, one unbreakable rule....When pressing down on the stone to be faceted do nor, I MEAN DO NOT OVERLY PUSH THE STONE DOWN AGAINST THE LAP!!! It will spring the arm out of alighnment, as in you bent it and it ain't fixable!!! Start with glass, it's pretty and cuts way faster than hard gemstone and polishes with cerium as versus expensive diamond stuff. Keep it wet under the cerium polish piece or it will slip and wrinkle and be messed up!

|

|

|

|

Post by Pat on Nov 21, 2016 1:09:54 GMT -5

orrum I have a box of pretty glass just for this purpose. I'll add it to my stack and probably start with it. Thanks for the tip.

|

|

micellular

has rocks in the head

Rock fever is curable with more rocks.

Rock fever is curable with more rocks.

Member since September 2015

Posts: 640

|

Post by micellular on Jan 12, 2017 19:05:51 GMT -5

3- various stick crystals to clean up  IMG_1128 IMG_1128 by Pat, on Flickr Hi Pat, It looks like you have some nice aquamarine and topaz crystals. You might want to save them as facet rough for when you're a little more comfortable. They should make some beautiful cut stones. |

|

|

|

Post by Pat on Jan 12, 2017 19:34:22 GMT -5

Thanks, Michelle,

Every step I take opens up a new expanding territory that needs considering.

I figured selecting starter stones had to be a no-brainer. Not so.

Progress is slow, but still moving along. Interest very much alive.

|

|

|

|

Post by Pat on Feb 19, 2017 18:28:18 GMT -5

Progress, but still nothing dopped. Had to move the entire setup to a different room. Acquired a desk with six drawers. Very helpful. gemfeller Joined USFG for $18 per year. Recognized the name (from here) of an officer. QuailRiver , found out the Facette was from Seattle, an older model. pauls The RayTech-Shaw came with a lot of material rough, laps and index wheels, does, some black wax and transfer jig etc. metalsmith , I bought Volume 1 of Herbst. It is just what I need --- very basic; lots of pictures etc I had never been even up close to a faceting machine and knew nobody who faceted. So impressed, I bought Volume 2. I haven't fired it up yet because I've never used dop wax or those fancy dop sticks. Yes, it is a huge learning curve. I figure the math won't kill me. Seems I just need to learn the formula and do it. Husband sis an engineer and can help I suspect. I've selected different stones to start with and will post photos in a minute. Intuition and thinking things through a good thing. Decided to do the quartz crystals on flat lap, since it was the sides and not the points that I wanted to clean up. I've matched the photos in the manual with what I have, and I think I have everything. Haven't dealt with the protractor yet or the index wheels. Now I know that at the frog is a free hopper and not tied down. I like that. Next is checking my new rock selections for flaws and deciding which end is up, then selecting an appropriate dop stick and doing it. Still need to understand the index wheels and what to set them to. One more thing: sold the Facette with accessories. Finally. I would really like to start faceting! Thanks for all the good advice. I was 100% lost. |

|

|

|

Post by Pat on Feb 19, 2017 18:45:42 GMT -5

Here is the entire setup. Drawers open so I can sort and identify all the disks.  IMG_1523 IMG_1523 by Pat, on Flickr ---------- Here is the new selection of stones.  fullsizeoutput_1567 fullsizeoutput_1567 by Pat, on Flickr Top row left to right: light yellow glass, garnet, and dark honey mystery rock Bottom row: small citrine, amethyst, and two small chunks of amethyst Now I need to check them out and make the final decision. Finally! |

|