cactusfire

starting to shine!

Member since September 2016

Posts: 31

|

Post by cactusfire on Sept 21, 2016 18:58:52 GMT -5

|

|

|

|

Post by Drummond Island Rocks on Sept 21, 2016 19:36:49 GMT -5

I have bought and sold a couple of the those and that is about what they go for. I picked one up for Jugglerguy a few years ago and he as posted about it several times. There is a post somewhere showing a lid/cover he made for it. I believe his only complaint was that the vise would occasionally lift up during a cut because it swivels on the guide rod. Chuck |

|

|

|

Post by Jugglerguy on Sept 21, 2016 21:34:22 GMT -5

Yep, I use this as my trim saw and for hand slagging small rocks. I like it a lot for that purpose. The cover I made doesn't get used because I haven't been able to figure out how to get the gravity feed vice to work. Too little weight and the rock doesn't move. Too much and it rides up the blade.

Someone else has one on here that's painted maize and blue. I can't remember who though.

|

|

cactusfire

starting to shine!

Member since September 2016

Posts: 31

|

Post by cactusfire on Sept 25, 2016 10:44:11 GMT -5

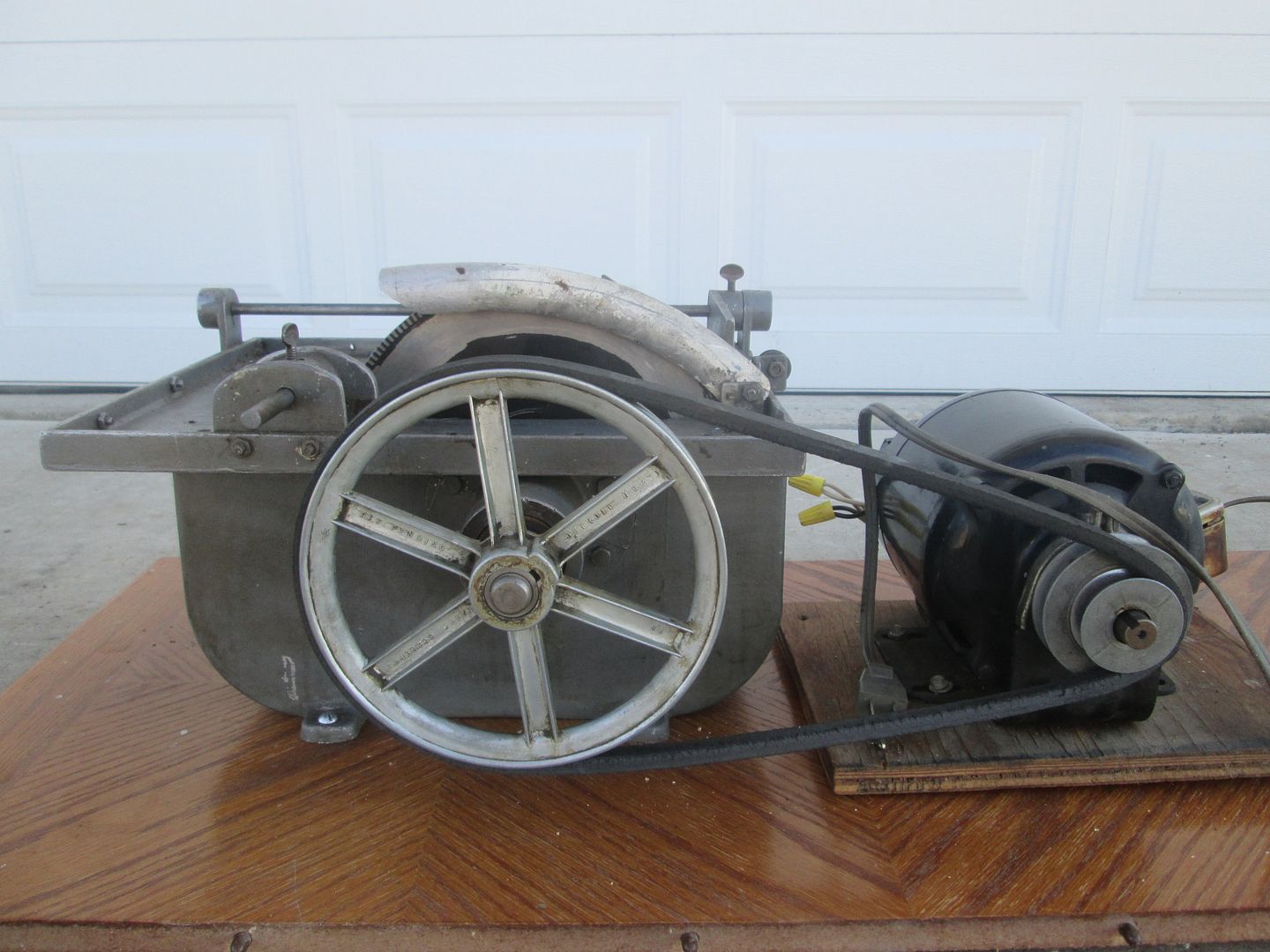

Yep, I use this as my trim saw and for hand slagging small rocks. I like it a lot for that purpose. The cover I made doesn't get used because I haven't been able to figure out how to get the gravity feed vice to work. Too little weight and the rock doesn't move. Too much and it rides up the blade. Someone else has one on here that's painted maize and blue. I can't remember who though. I went ahead and purchased the saw. Used saws just don't seem to be available in my area that often. However I have buyers remorse. After I brought the saw home and looked at some pictures online of the same saw I realized the pulley on mine is a lot larger than maybe it should be. Also the blade has some side to side movement about a sixteenth of an inch. When I plugged it in I was surprised with the direction the blade was spinning. I assumed it would spin so the rock is being cut on the down ward stroke of the blade but the blade spun so it would cut on the upward stroke. Is that how it is suppose to cut?   |

|

barclay

has rocks in the head

Lowly Padawan of rocks

Lowly Padawan of rocks

Member since November 2011

Posts: 510

|

Post by barclay on Sept 25, 2016 11:34:34 GMT -5

I think something is wrong. If the blade is spinning "up" the oil is not going to be captured by the guard. Whoever made this unit likely wired the motor in reverse.

|

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Sept 25, 2016 11:42:40 GMT -5

Most lapidary saws use a motor with approximately 1725 rpms. If that motor's rpm rating is in that neighborhood then yes that pulley is MUCH too large. And IMO that large open pulley is a safety hazard too. And yes you are correct in that the blade should cut on the "downward stroke". Just remount the saw and motor with the motor facing the opposite direction and that will take care of the issue of the direction of rotation of the blade. If the plate on the motor says it's 1725 rpms you'll only need to replace the blade arbor pulley and they are less than $10 at most any hardware stores. The blade on that saw looks to be an old MK-297 Criterion Blade which was the predecessor to the BD/MK-301 blade. MK recommends an rpm speed range of 1150-1720 for their 10" notched rim 301 blade. www.mkdiamond.com/lapidary/tec_speed.htmlAnd after checking your motor speed here is a link to a site with an rpm/pulley size calculator to help you determine pulley sizes needed. mgfic.com/rpm_calc.aspIf the motor on the saw is a compressor motor with a high rpm rating (like 3450 or so) then I'd recommend replacing the motor with a 1/3hp continuous-duty motor with 1725 (or close) rpm rating. If the 1/16" movement of the blade is from arbor movement then you probably need to replace the bearings. If its just wobble in the blade then the blade will probably still be usable. Just take it slow when initially starting to feed the rock into the blade. Larry C. |

|

cactusfire

starting to shine!

Member since September 2016

Posts: 31

|

Post by cactusfire on Sept 26, 2016 7:20:42 GMT -5

Most lapidary saws use a motor with approximately 1725 rpms. If that motor's rpm rating is in that neighborhood then yes that pulley is MUCH too large. And IMO that large open pulley is a safety hazard too. And yes you are correct in that the blade should cut on the "downward stroke". Just remount the saw and motor with the motor facing the opposite direction and that will take care of the issue of the direction of rotation of the blade. If the plate on the motor says it's 1725 rpms you'll only need to replace the blade arbor pulley and they are less than $10 at most any hardware stores. The blade on that saw looks to be an old MK-297 Criterion Blade which was the predecessor to the BD/MK-301 blade. MK recommends an rpm speed range of 1150-1720 for their 10" notched rim 301 blade. www.mkdiamond.com/lapidary/tec_speed.htmlAnd after checking your motor speed here is a link to a site with an rpm/pulley size calculator to help you determine pulley sizes needed. mgfic.com/rpm_calc.aspIf the motor on the saw is a compressor motor with a high rpm rating (like 3450 or so) then I'd recommend replacing the motor with a 1/3hp continuous-duty motor with 1725 (or close) rpm rating. If the 1/16" movement of the blade is from arbor movement then you probably need to replace the bearings. If its just wobble in the blade then the blade will probably still be usable. Just take it slow when initially starting to feed the rock into the blade. Larry C. Thank you so much for all that information. The motor is listed at 1725 rpm. I am going to take your advice and mount a smaller pulley and turn the motor around. |

|

|

|

Post by Peruano on Sept 26, 2016 7:29:42 GMT -5

there's a chance that the direction of the motor's rotation can be changed by reversing two of the wires on the motor. Look carefully for clues as whether that is an option (easier than moving the motor, but not possible on all motors). That big pulley is hard to explain, but someone wanted things to go real slow.

|

|

cactusfire

starting to shine!

Member since September 2016

Posts: 31

|

Post by cactusfire on Sept 26, 2016 18:46:21 GMT -5

What speed should I shoot for if I am cutting mostly agates?

|

|

QuailRiver

fully equipped rock polisher

Member since May 2008

Posts: 1,640

|

Post by QuailRiver on Sept 26, 2016 19:47:19 GMT -5

The faster the blade spins the more spray and mist it will create. So since this is an open saw (no hood to contain the spray and mist) I'd be inclined to stay on the lower end of the 1150-1720 recommended rpm range. And also since this saw doesn't have a powerfeed you can just adjust your gravity feed rate or hand feed rate to the chosen blade speed.

Larry C.

|

|

|

|

Post by johnjsgems on Sept 27, 2016 10:32:06 GMT -5

Use the pulley chart mentioned and size to the smaller motor pulley. You can use the larger motor pulley if you later change to 303C or new style 301 blade. Most modern motors have a red and black lead in the terminal area thet you reverse to change direction. Should say on motor tag. My first saw was same Frantom 10". Was in a guy's yard full of rain water, no motor and blade completely rusted through. It had "barnacles" growing in the aluminum sump and I used a 6' cheater bar to force the bearings to turn. A used motor, new blade and belt and I was able to use it for a while but bearings were very noisy. I eventually replaced bearings (found exact replacements through an ag supply by numbers on bearings) and used saw for years for hand trimming and slabbing. Found vise rod bushings at Ace Hardware in pull out drawers. Sold it for $300 later. Frantom was every bit as good as original Highland Park. And for trivia sake you should know they were made by a couple "Fran" and "Tom" hence the name.

|

|

minerken

Cave Dweller

Member since August 2013

Posts: 466

|

Post by minerken on Sept 27, 2016 10:49:12 GMT -5

a quick tip just turn the motor 180 degrees (if you have the room)it will rotate properly no need to re-wire which may or may not be possible.

|

|

|

|

Post by Rockoonz on Sept 27, 2016 16:44:35 GMT -5

Yep, I use this as my trim saw and for hand slagging small rocks. I like it a lot for that purpose. The cover I made doesn't get used because I haven't been able to figure out how to get the gravity feed vice to work. Too little weight and the rock doesn't move. Too much and it rides up the blade. Someone else has one on here that's painted maize and blue. I can't remember who though. Swedish flag theme. Sold it years ago. The gravity feed didn't work well for me either. I used lath wood between the vice jaws and rock to get a better grip on problem rocks and pushed the vice by hand, holding down on it so it wouldn't ride up the blade and bind.  |

|

|

|

Post by Jugglerguy on Sept 27, 2016 19:29:12 GMT -5

I don't use the vice at all any more. I do like the little fence that comes in from the right. I use it to hand slab small rocks.

|

|