|

|

Post by mohs on Jan 15, 2016 15:52:16 GMT -5

That file set-up just rocks, Adrian!

I recall/similar setup from the last project

In my way of thinking the sanding would come after the file work

but your such a master filer

your probably smoother that 10,000 grit paper ha ha

whatever you choose, Adrian

its gonna be a damn sharp shine!

Ed

|

|

|

|

Post by mohs on Jan 15, 2016 15:53:43 GMT -5

and I like that rolled up sanding setup

gives a bit hollow grind to the edge

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jan 15, 2016 23:06:35 GMT -5

Thanks, Ed! The jig is not only similar, it's the very same I used in the previous projects (sword and meteorite knife). and I like that rolled up sanding setup gives a bit hollow grind to the edge I was also thinking to hollow grind the edge on the curved side of the sander but I don't think I could get an even curvature, so I let it straight. Adrian |

|

|

|

Post by mohs on Jan 15, 2016 23:15:06 GMT -5

I hear ya

& straight on that sort blade is probably best

stronger edge...

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jan 26, 2016 7:56:00 GMT -5

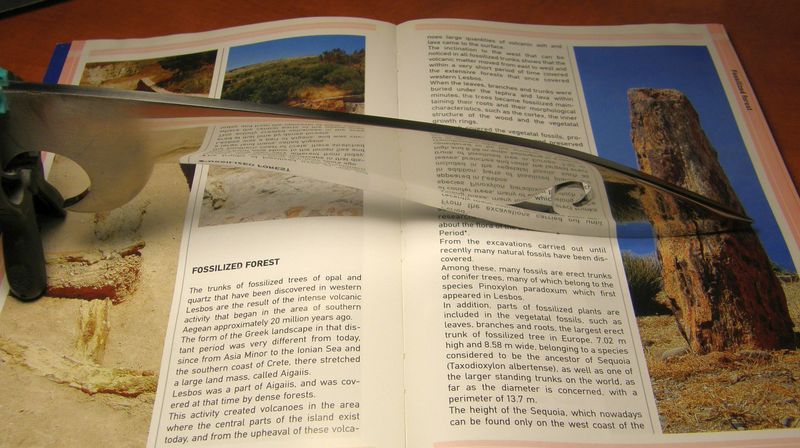

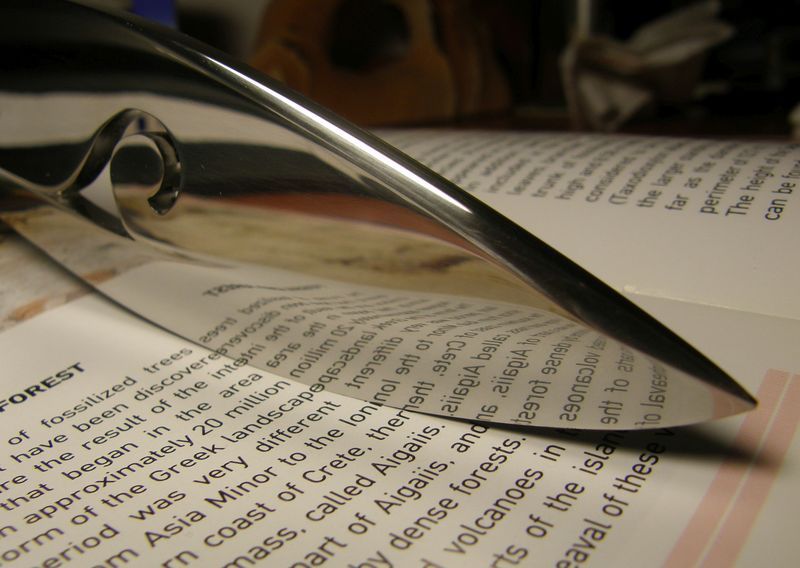

Hello again! Time for a new update. The blade is polished by now. Let me show you some pics from the progress of this work. Firstly, I drilled some holes in what would become the hollow wave zone:  Then, using some small thin files, I merged the holes and gadually turned them into the hollow shape:  After that, I polished the blade using sand paper from coarse to fine in the following steps: 150, 280, 500, 800, 1000, 1500, 2500, 3000. All the sanding process was made like this:   And here are some picture of the blade after the final polish:    The blade is protected by now to avoid the scratches and I focussed on the bolsters. I was already shaping them roughly and now I am going to bring them to the size of the blade's handle. This will be the subject of the next update. Till then, thank you for looking and for your replies. Adrian |

|

|

|

Post by kk on Jan 26, 2016 8:25:28 GMT -5

Fabulous. Just amazing watching your process.

|

|

|

|

Post by captbob on Jan 26, 2016 9:09:47 GMT -5

Been following and this "knife" just went from "that's interesting" to "that's outstanding!"

Thank you for bringing us along for the ride.

Looking forward to the finished piece.

|

|

|

|

Post by connrock on Jan 26, 2016 9:41:46 GMT -5

Adrian you are one amazing man!!!

To work with stainless steel like you do is amazing to me!

If I cut 2 pieces of angle iron with a hack saw I have to sit with a heating pad at night and use an electric massage on my shoulder!

You are not only a master craftsman,,,you also have the hands,arms and shoulders as strong as a gorilla!

I look forward to seeing you work on this knife!

connrock

|

|

Fossilman

Cave Dweller

Member since January 2009

Posts: 20,718

|

Post by Fossilman on Jan 26, 2016 10:05:07 GMT -5

OUTSTANDING WORK!!!!

|

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Jan 26, 2016 12:25:51 GMT -5

Fabulous! Extremely interesting. Love it. But my friend, as much as I know, in Romania you need to have a permit for this cold weapon.  |

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jan 26, 2016 14:47:09 GMT -5

Fabulous! Extremely interesting. Love it. But my friend, as much as I know, in Romania you need to have a permit for this cold weapon.  Thank you Zoran. The knife isn't not cold, especially after rubbing it so much with the sand paper  Besides, I don't sharpen the edge - in fact I purposely dull it, so a good kitchen knife, a long screwdriver or an axe are far more dangerous than this knife. Adrian |

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jan 26, 2016 14:53:17 GMT -5

Adrian you are one amazing man!!! To work with stainless steel like you do is amazing to me! If I cut 2 pieces of angle iron with a hack saw I have to sit with a heating pad at night and use an electric massage on my shoulder! You are not only a master craftsman,,,you also have the hands,arms and shoulders as strong as a gorilla! I look forward to seeing you work on this knife! connrock Thank you Tom! Gorilla you say, huh? My arms and shoulders also ache, but I enjoy this side of knife making: the physical exercise. I should do this more often. In fact I did some a couple of weeks ago, when I shoveled the snow from the yard. Must have been a good training for hand sanding and polishing this blade. Adrian |

|

Sabre52

Cave Dweller  Me and my gal, Rosie

Me and my gal, Rosie

Member since August 2005

Posts: 20,492

|

Post by Sabre52 on Jan 26, 2016 16:47:22 GMT -5

Watching the progress of your artwork is one of my favorite things. Man, what a polish you've gotten on that blade. Beautiful!.....Mel

|

|

|

|

Post by mohs on Jan 26, 2016 17:21:48 GMT -5

file agile

sanders hand

polished metal

mirrored grand

blade-maker medal

mohs

|

|

|

|

Post by MrP on Jan 26, 2016 19:38:33 GMT -5

Fantastic a always!!!!!!!!!!!!!!!.......MrP

|

|

Deleted

Deleted Member

Member since January 1970

Posts: 0

|

Post by Deleted on Jan 26, 2016 22:44:52 GMT -5

Knives illegal without permit in Romania? How do you cut your cheese, or onions, or sandwich meats? adrian65 |

|

Zoran

freely admits to licking rocks

Member since September 2005

Posts: 880

|

Post by Zoran on Jan 27, 2016 8:54:12 GMT -5

Knives illegal without permit in Romania? How do you cut your cheese, or onions, or sandwich meats? adrian65 I was joking. But in every joke there is some truth.  I don't know exactly for Romania, but here in Serbia it is illegal to carry a knife with a blade longer than 12 cm (a bit shorter than 5 inch). |

|

bushmanbilly

Cave Dweller

Member since October 2008

Posts: 4,719

|

Post by bushmanbilly on Jan 28, 2016 15:11:04 GMT -5

Beautiful work of art. Adrian

|

|

|

|

Post by connrock on Jan 30, 2016 9:52:46 GMT -5

Adrian,

It is hard for me to justify spending money on tools and equipment for a hobby and being on a monthly pension but after years of many sleepless nights with aching shoulders and arms I just bought a portable metal band saw with a table!

I will now take all of my hacksaws to the shooting range and use them as targets! LOL

I can't throw out my snow shovel,,,,yet!I even tried to "introduce" my wife to the snow shovel but for some reason she didn't want to meet it! LOL

Good luck with the knife!I KNOW it will e a thing of beauty!

connrock

|

|

adrian65

Cave Dweller  Arch to golden memories and to great friends.

Arch to golden memories and to great friends.

Member since February 2007

Posts: 10,790

|

Post by adrian65 on Jan 31, 2016 3:16:31 GMT -5

Hello, friends! Here's a new update. After finishing the blade, my work focussed on the handle. I started with the bolsters. This handle is a bit more special, as it has not two pairs of bolsters, but three of them (as you will see in the next pics). The rear bolsters are shaped as a horse head and the front ones are a flowing shape which I changed compared to my first design (see page 1 of this thread). Firstly, I drew the cardboard templates for the front and rear bolsters:  Then I cut them from the same stainless steel sheet from which the blade is made. I drilled the roughly shaped bolsters, overlapped them on the handle...  ... and started to grind the excess. Firstly, with the angle grinder...  ... and then, with coarse files...   ... and, finally, with smooth files:  After this, I removed the bolsters from the handle and I cut the horse's ear in the middle, to give to the remaining ears a more realistic look  I also started to work at the other bolsters, but they're not yet ready. So, I can tell you straight from the horse's mouth that this is how the handle looks now:   Thank you for looking, Adrian |

|